OFBV6 Series

Forged High Pressure Ball Valves

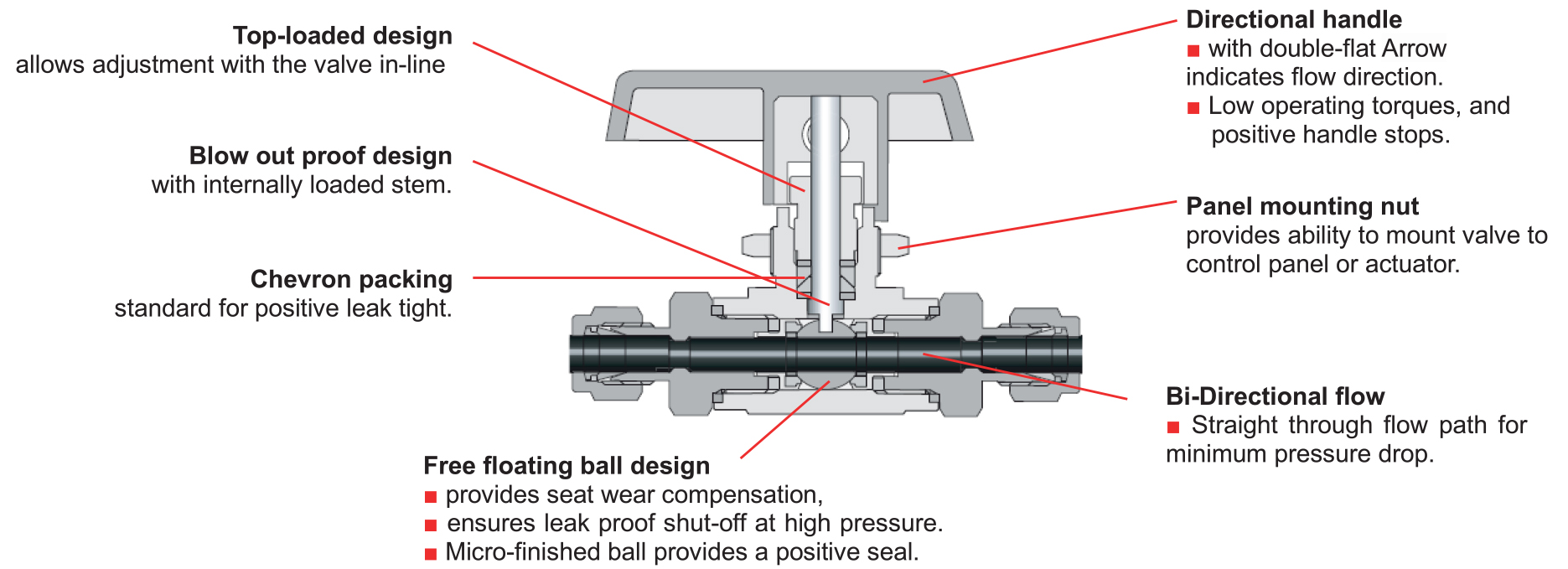

Features

■ Pressure rating up to 6,000psig (413var)@70°F(21°C).

■ Temperature rating from -65°F(-54°C) to 350°F(177°C) with Standard PCTFE seat.

Application

■ Gas

■ Water

■ Oil

■ Petrochemical

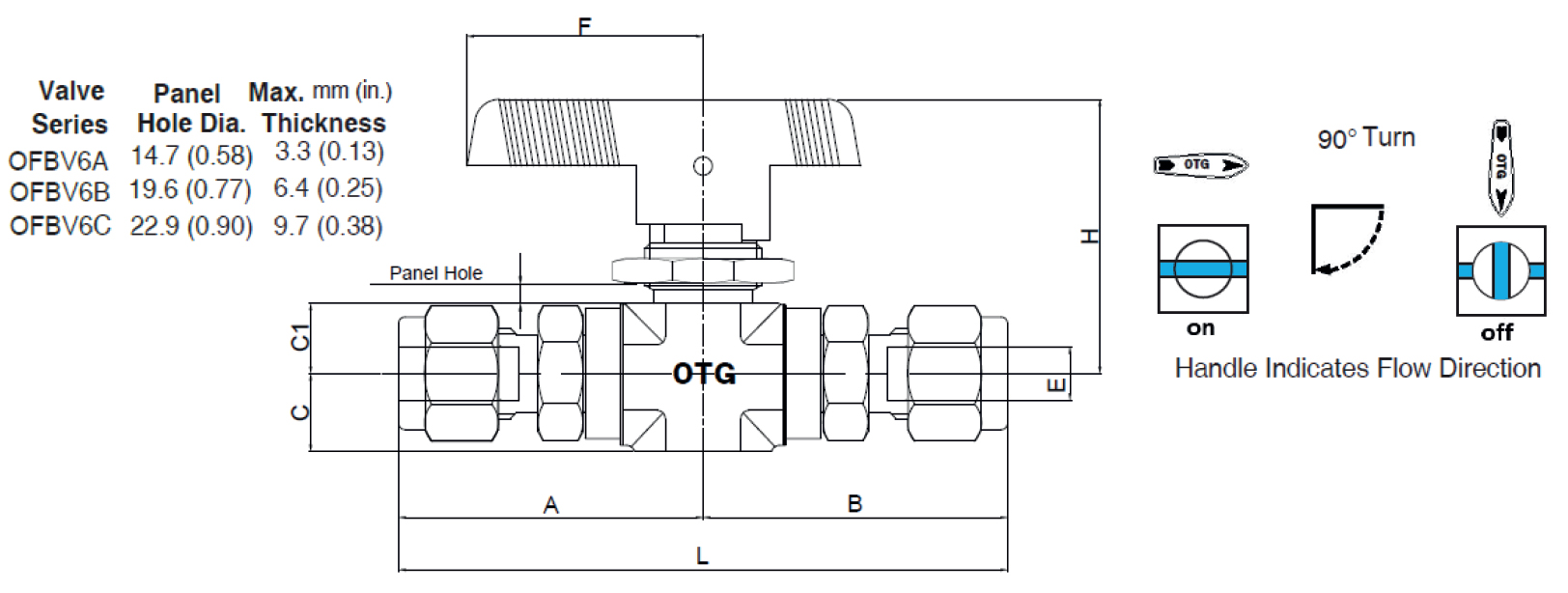

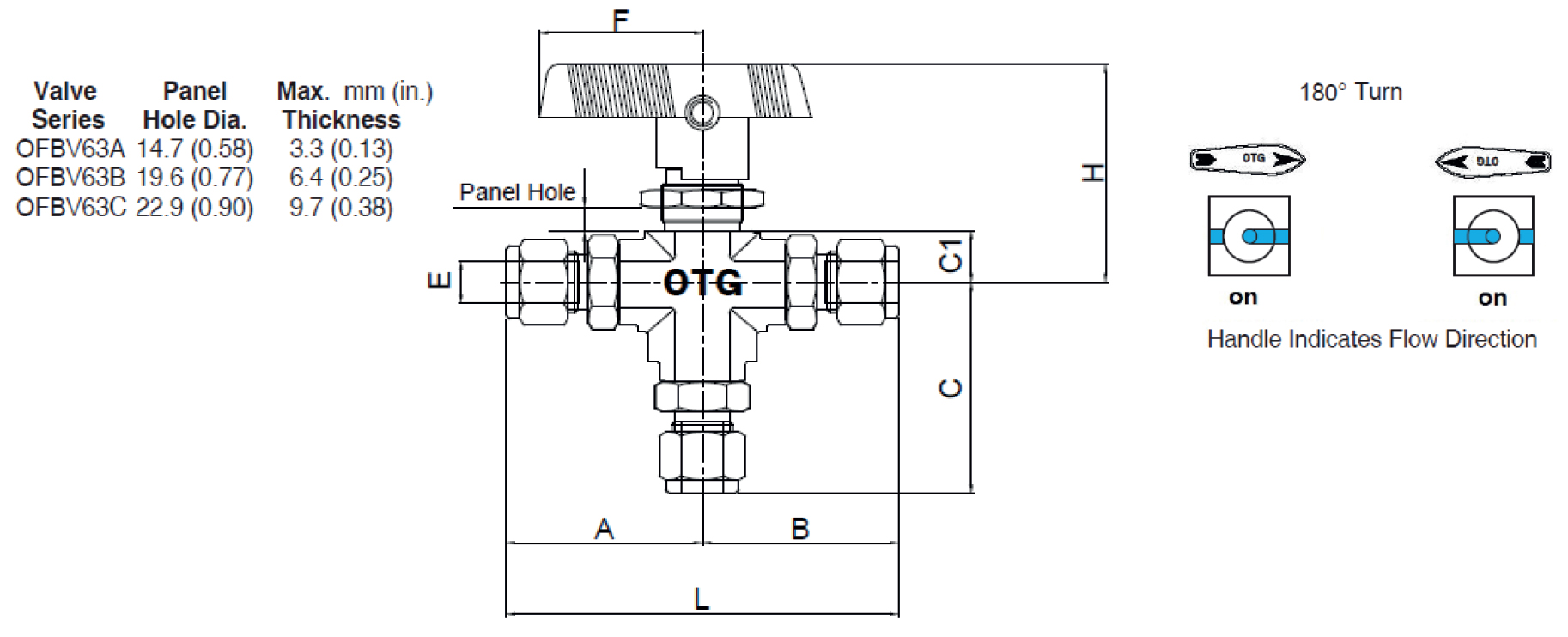

Operation

2-Way valves are designed to isolate fluid in off position, 3-Way valves are to divert fluid taking it from bottom inlet port

■ Valves provide excellent performance in gas, liquid and vacuum in process control and instrumentation application.

■ Valve are designed to control fluid in full open or in full closed position; using the valve to throttle the fluid may reduce valve cycle life.

■ Valve that have not been actuated for a period of time may have a higher initial actuation torque.

Testing and Cleaning

■ Every valve is factory tested with nitrogen @ 1000 psig (69 bar)) for leakage at the seat to a maximum allowable leak rate of 0.1 SCCM.

■ The packing is tested with nitrogen for no detectable leakage.

■ Every valve is cleaned and packaged in accordance with OTG cleaning standard.

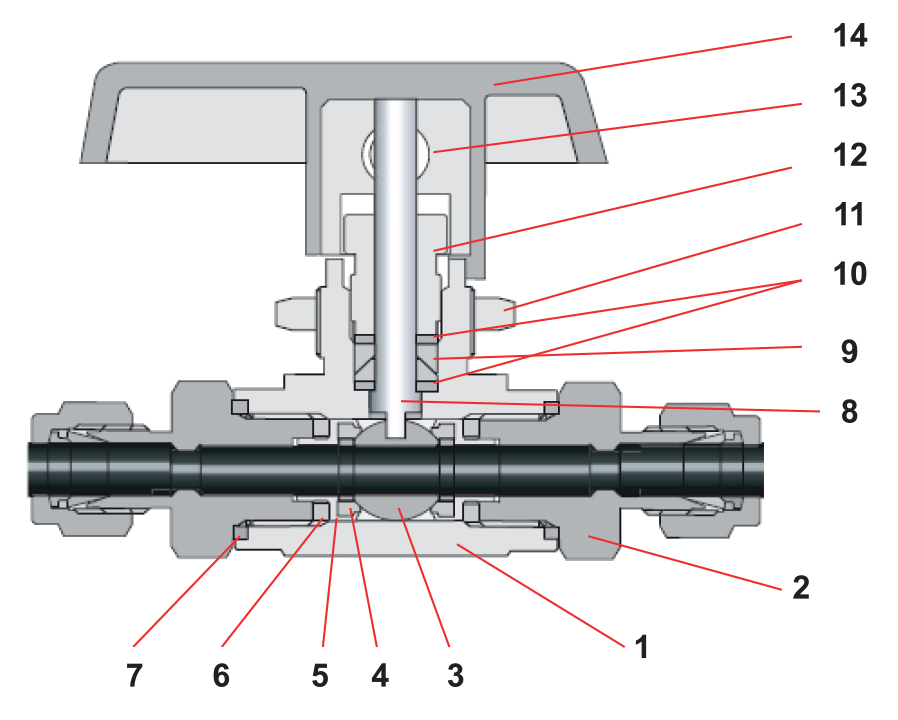

Packing Adjustment Procedure

Packing adjustment may be periodically required to prevent leakage.

- Depressurizw the system

- Cycle and purge the valve.

- Remove the handle from the valve.

- Turn the packing bolt clockwise in 1/16-turn increment until the valve achieves the leak-tight performance.

- Re-assemble the handle back in the valve.

Sour Gas Service

Valve materials are selscted in accordance with NACE MR0175/ISO 15156-3.

To order valve for sour gas application, insert"SG" to the valve basic ordering number. Example: OFBV6A-O-4T-SG-SS

Safe Valve Selection

The selection of a valve for any application or system must be considered to ensure safe performance. Valve rating, valve function, material compatibility, proper installation, operation, and maintenance remain the sole responsibility of the system designer and the user.

OTG Corperation accepts no liability for any improper selection, compatibility, installation, operation, or maintenance.