OBV3 Series

One-piece Ball Valves

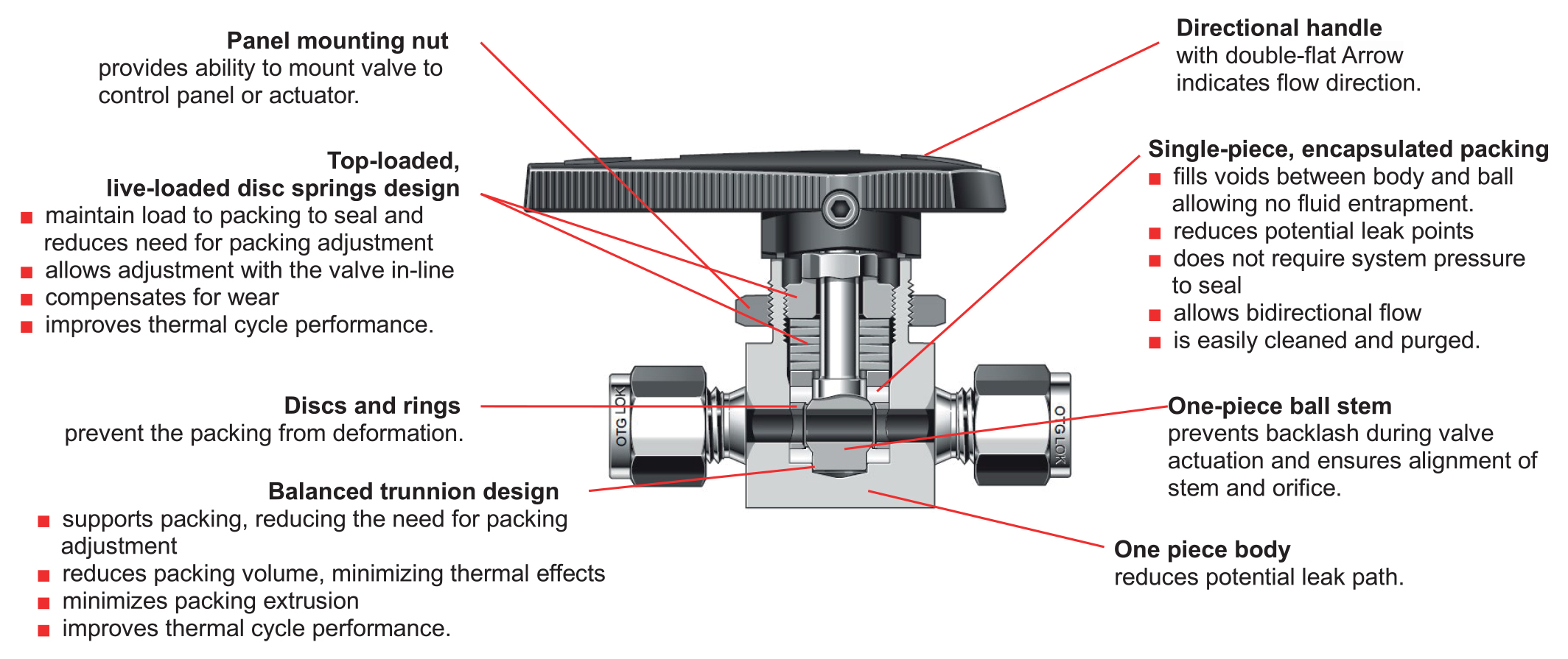

Features

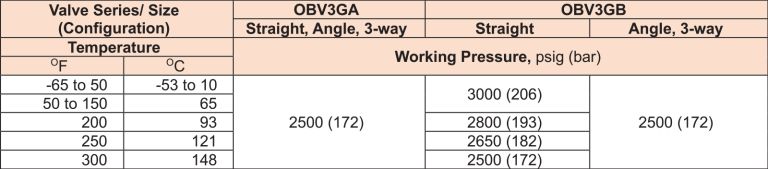

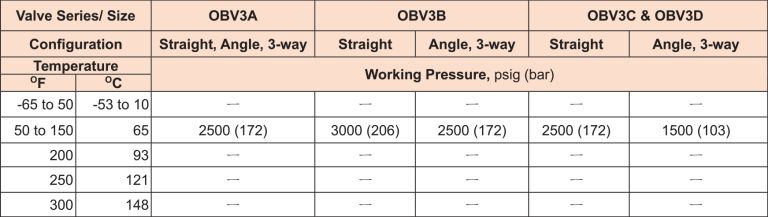

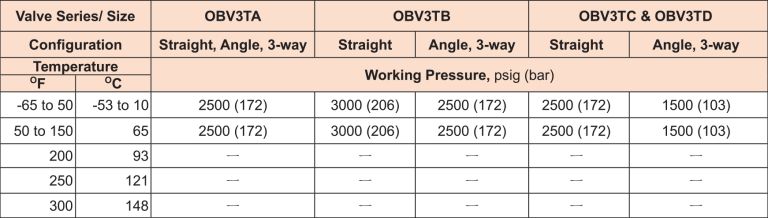

- Working pressure Up to 3000 psig (206 bar)

- Temperatures from -65 to 300°F (-53 to 148°C)

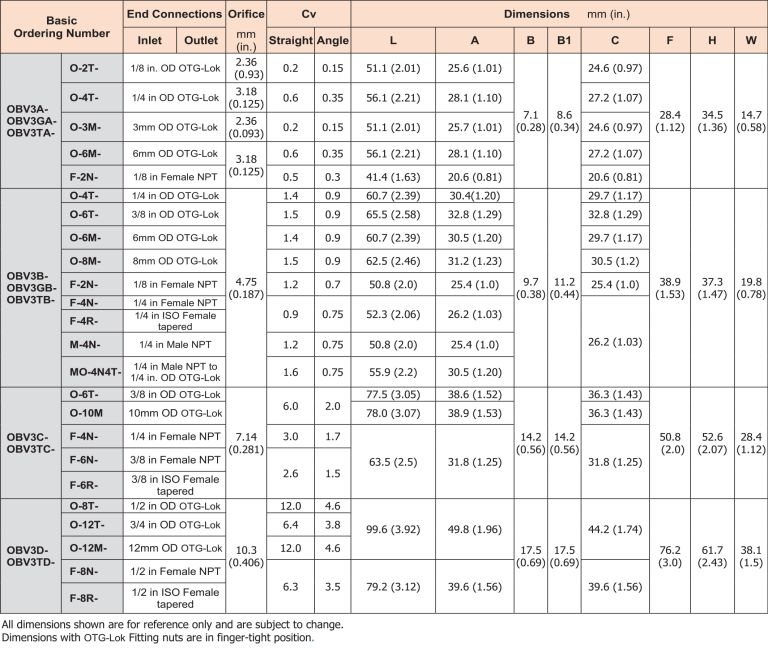

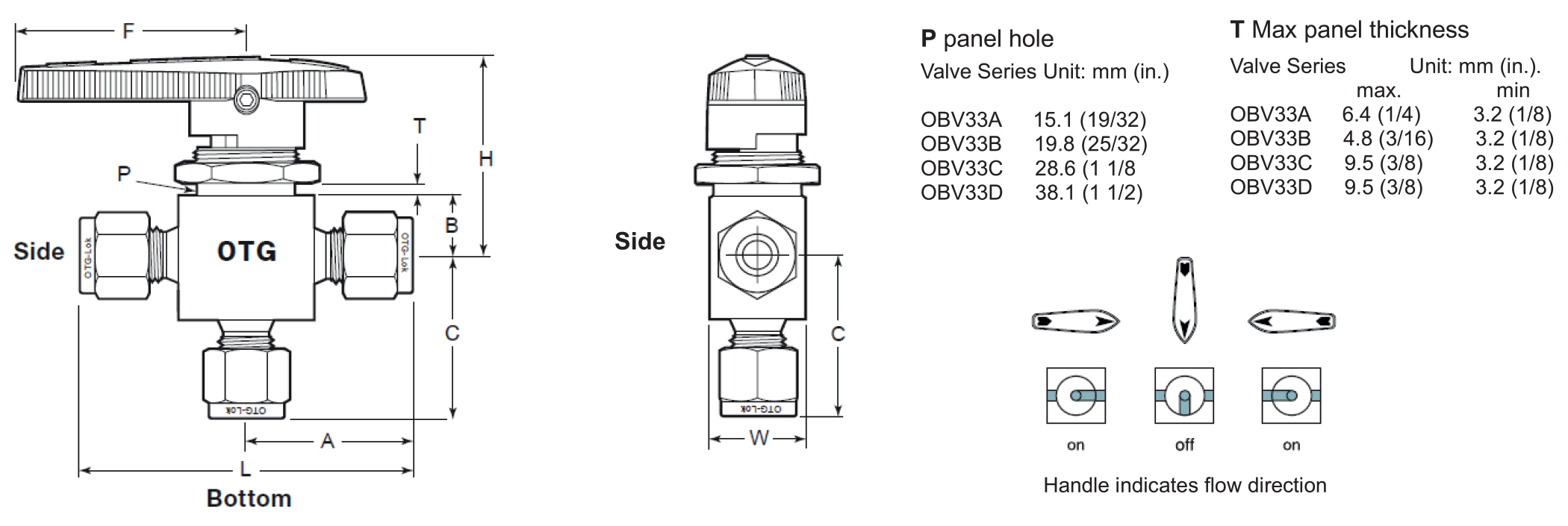

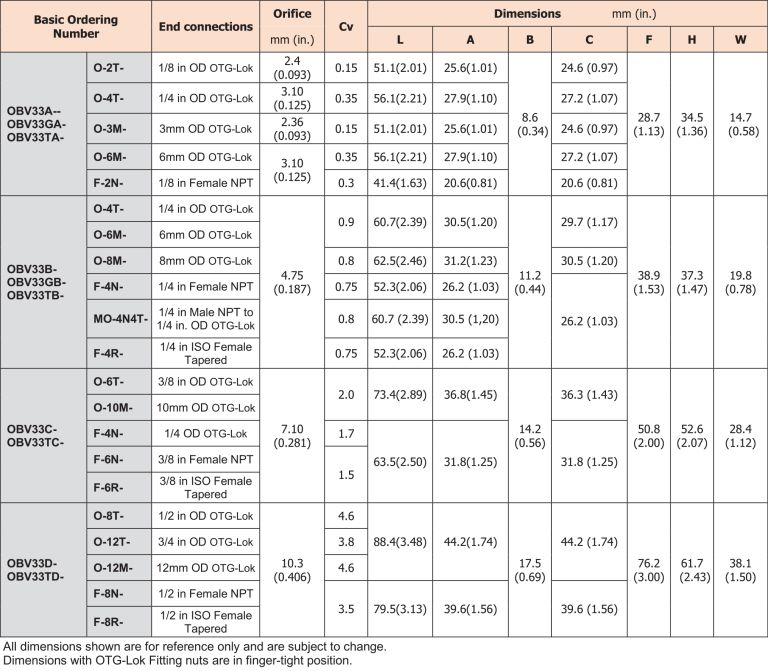

- 1/8 to 1/2 in. (3 to 12 mm OD)

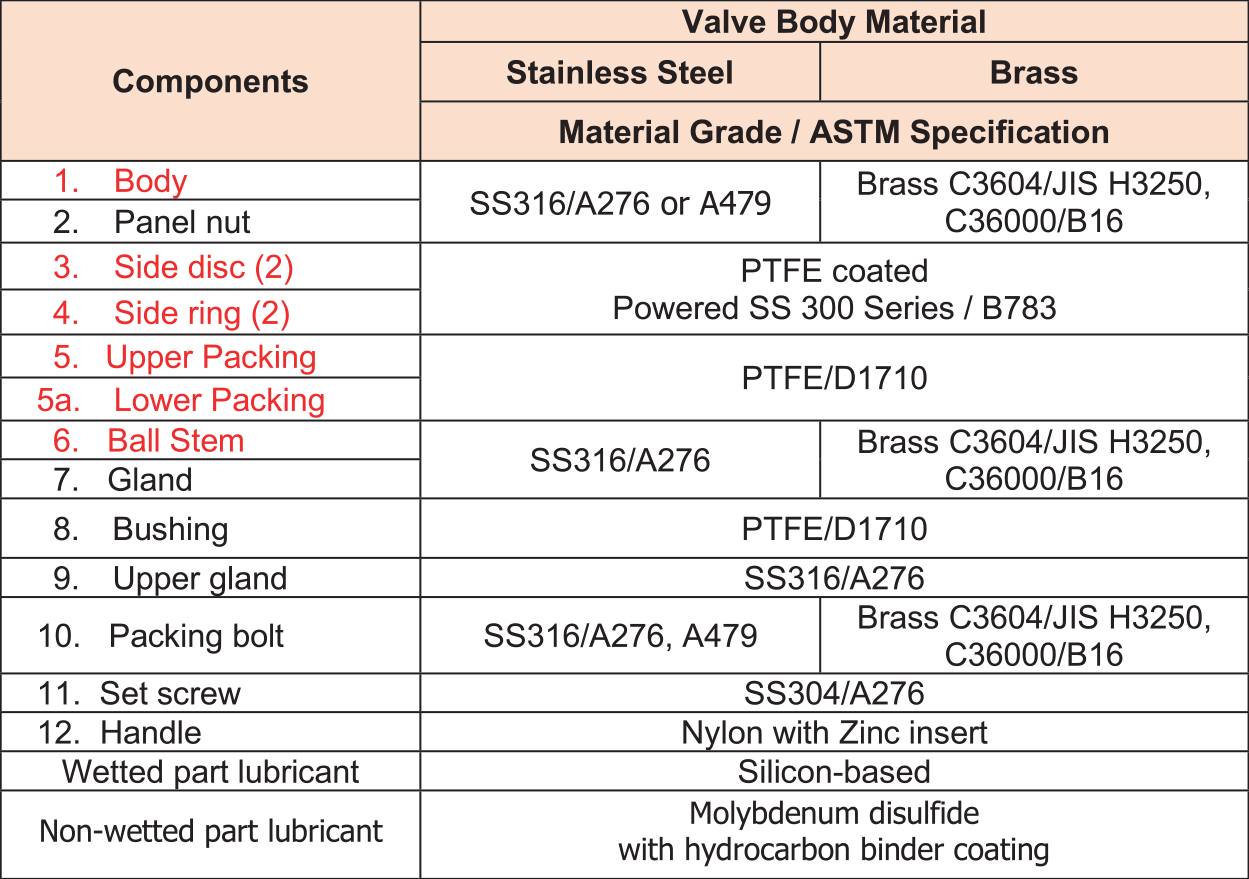

- Stainless Steel, Brass

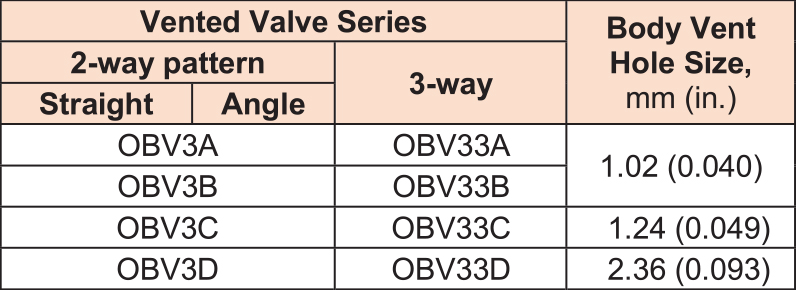

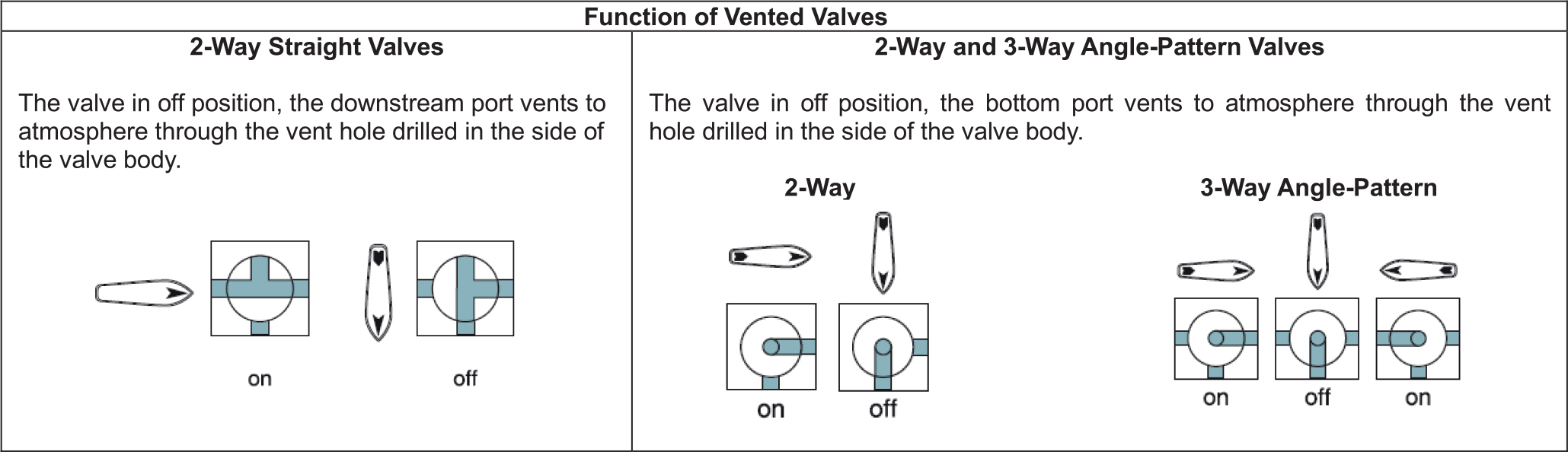

Vented Valves

Metal Handle

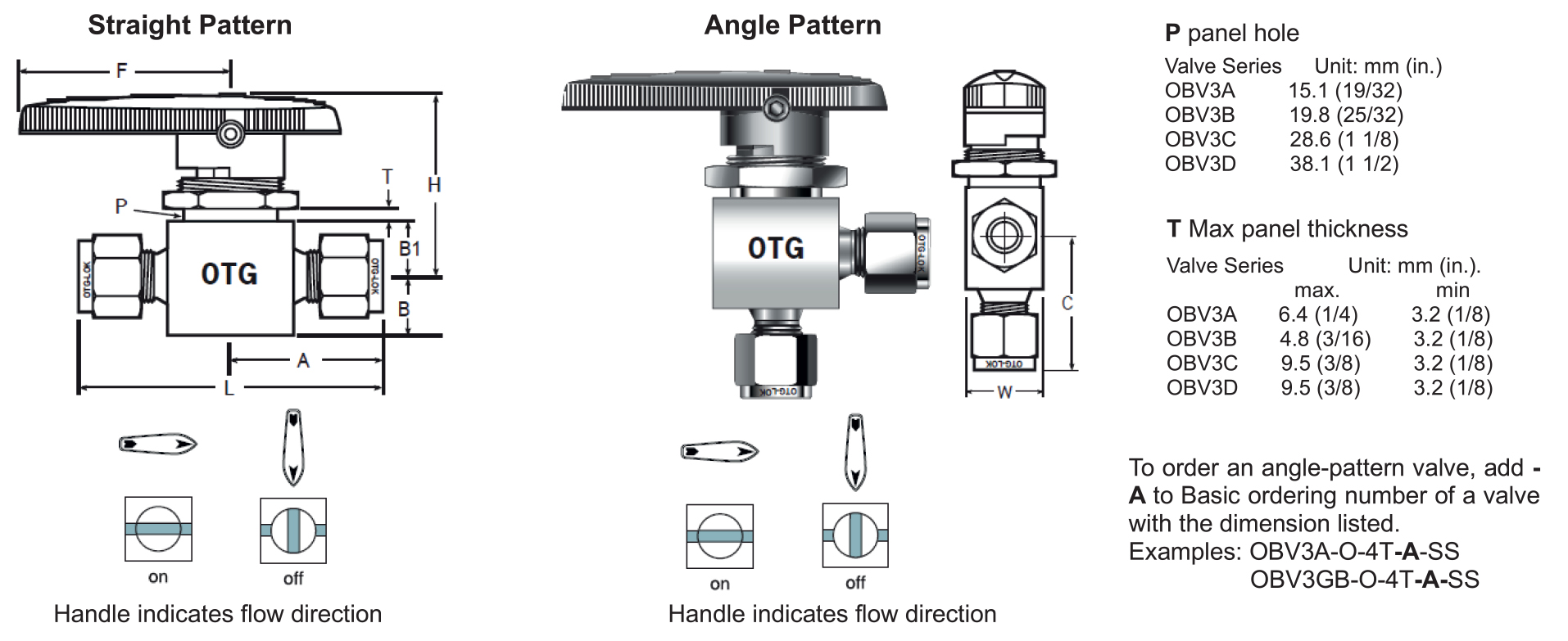

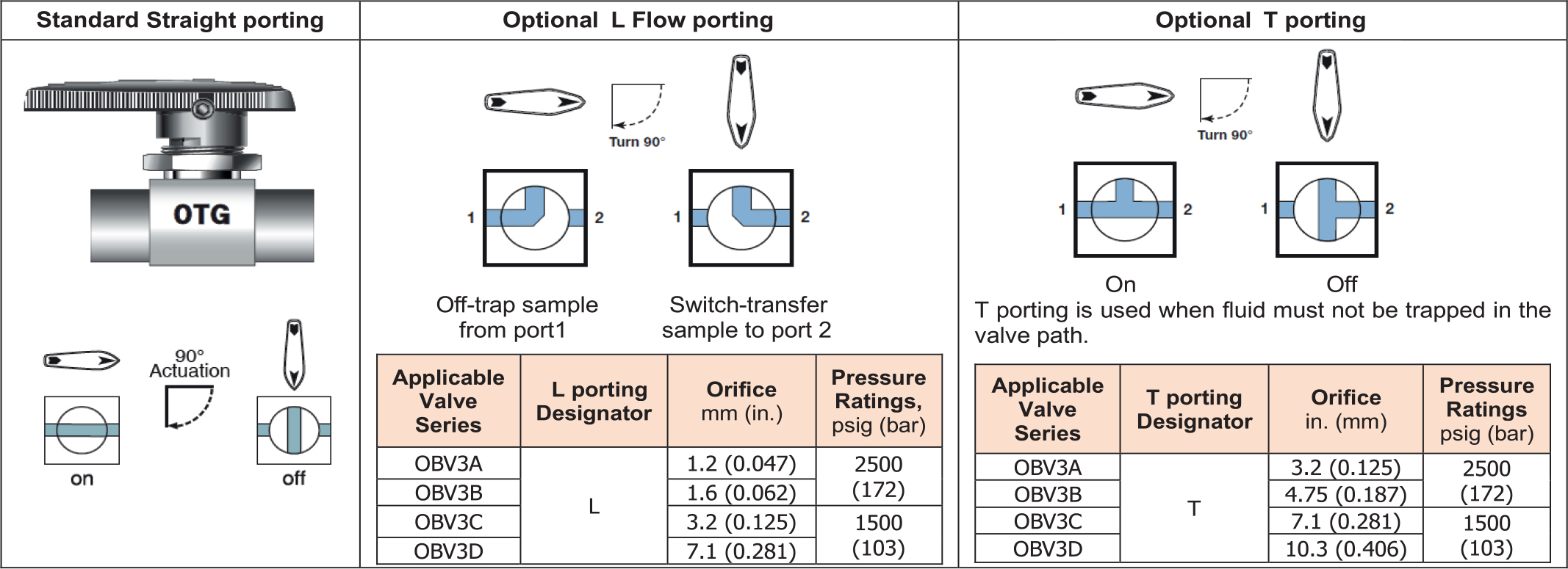

2-Way Straight, Angle Patten, and 3-Way

Meral handle is useful for actuating valve in an elevated temperature. Stainless steel or Aluminum materials are available.

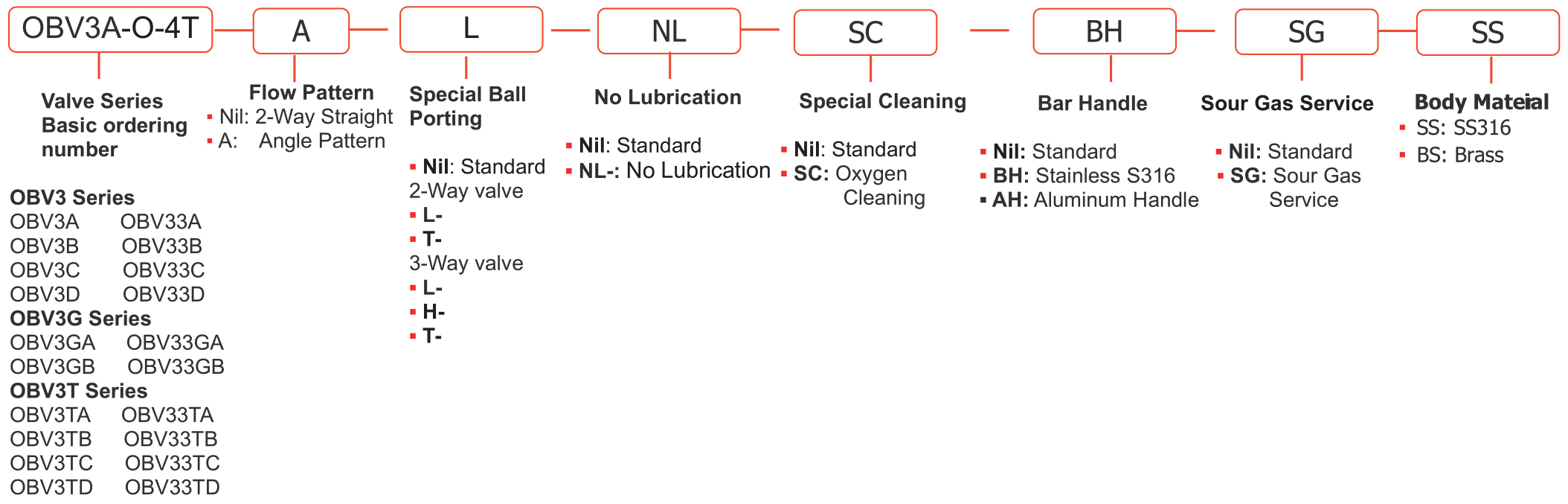

To order factory-assembled metal handle on the valve, add-BH or - AH to the valve Basic ordering number.

Example: OBV3B-O-4T-BH-SS

Aluminum handle is supplide with Black anodized.

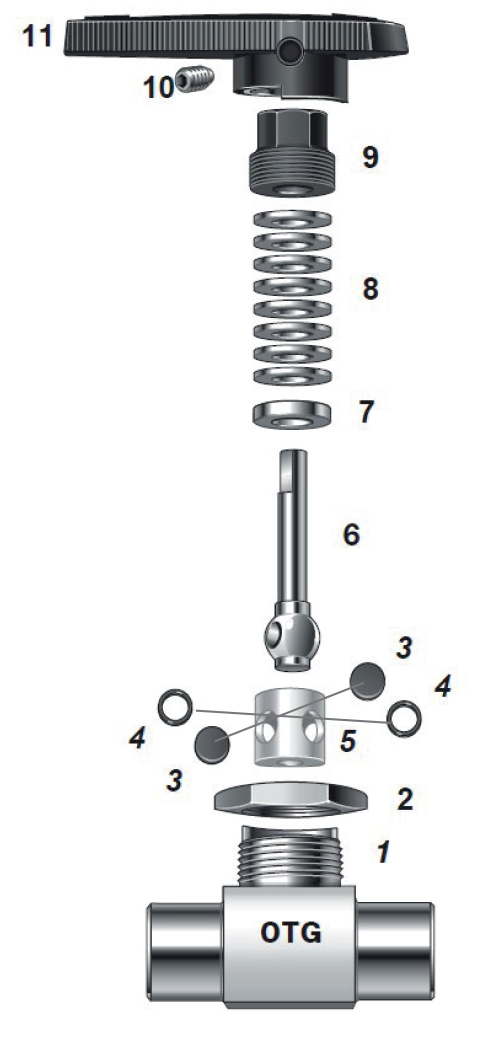

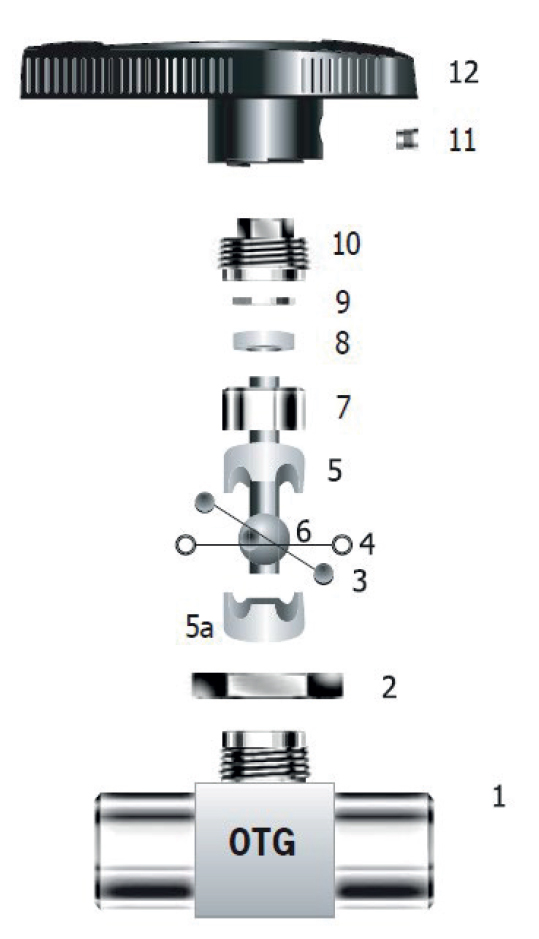

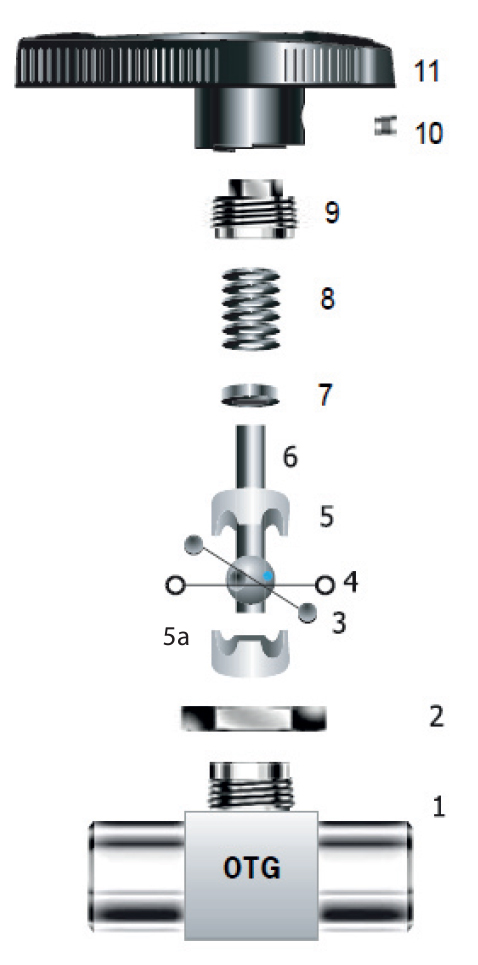

Packing Adjustment Procedure

■ Packing adjustment may be periodically required to prevent leakage and to increase service life.

■ Live loaded packing disc springs allow the packing adjustment with the valve in-line.

1. Depressurize the system.

2. Cycle and purge the valve

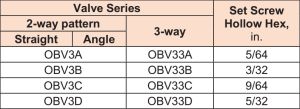

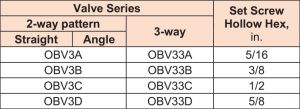

3. Using the Allen Hex Key corresponding to the size of Set Screw Hollow Hex as indicated in the table bolow, turn on the handle counter-clockwise and remove the handle from the valve.

4. To adjust the packing, turn the packing bolt clockwise in 1/16 turn increment until the valve achieves the leak-tight performance.

5. Re-assemble the handle back in the valve.

Factory Test and Cleaning

- Every valve is factory tested with nitrogen @t 1000 psig (69 bar) for leakage at packing to a maximum allowable leak rate fo 0.1 std cm3/min.

- Every valve is cleaned and packaged in accordance with OTG cleaning standard of CS-01. Special cleaning standard of CS-11 in compliance with ASTM G93 Level C is optinal.

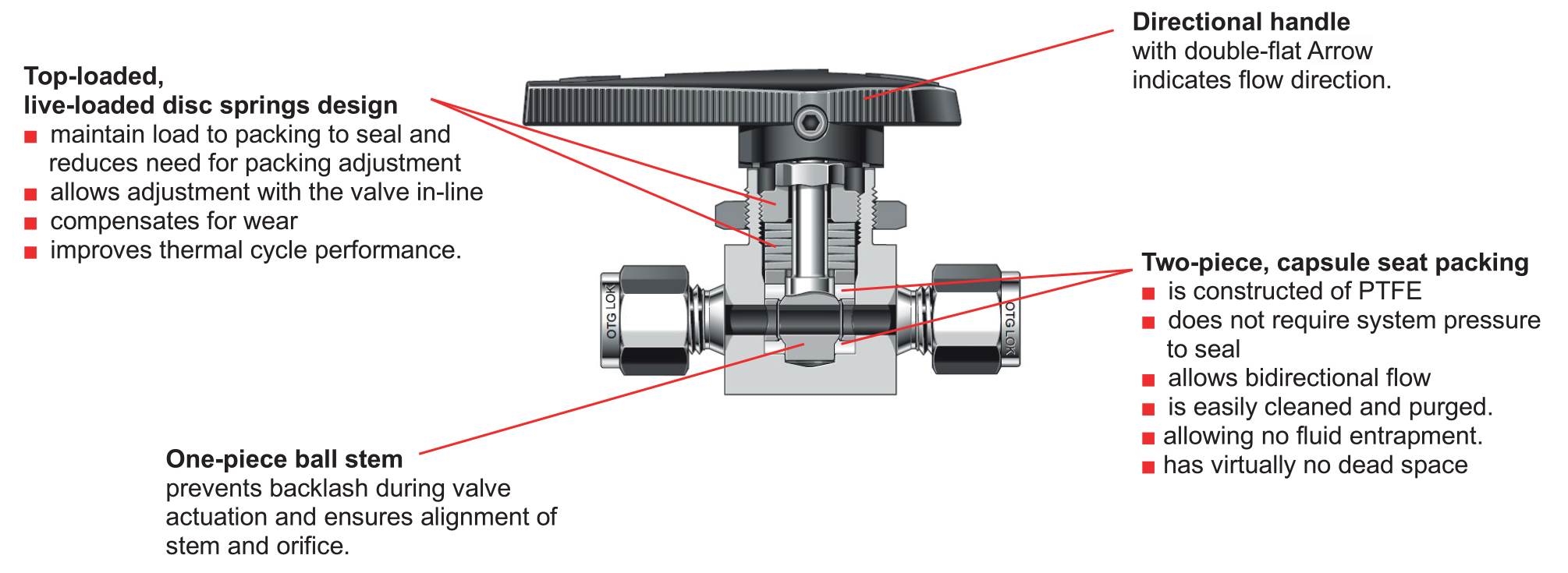

Application

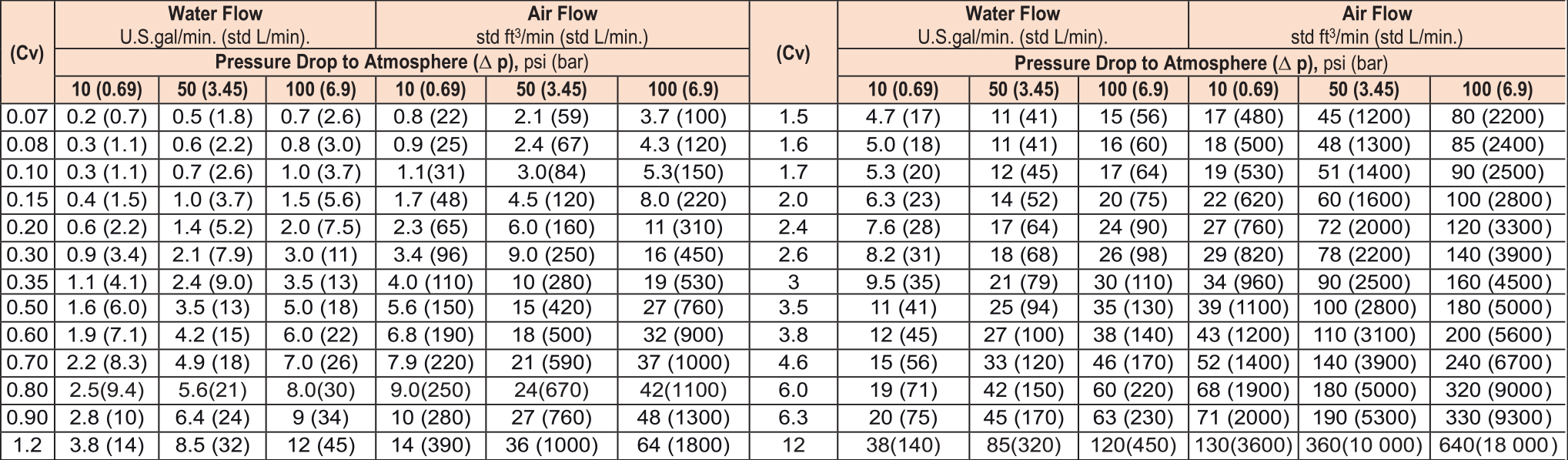

■ Analytical industry requires a valve with the lowest dead volume to prevent fluid entrapment minimizing contamination.

■ Control sampling system and process instrumentation require a valve with compact size, high flow capacity and directional indication of flow.

Operation

■ OBV3 series valves ard designed to control fluid in full open and full close position; using the valves to throttle the flow may reduce the valve service life.

■ Valves that have not been actuated for a period of time may have a higher initial actuation torque.

■ The working pressure of every valve is adjusted for factory test at 1000 psig (69 bar) @ 21°C (70°F). For use in higher pressure, the valve packing may be required for re-adjustment.

Special Cleaning

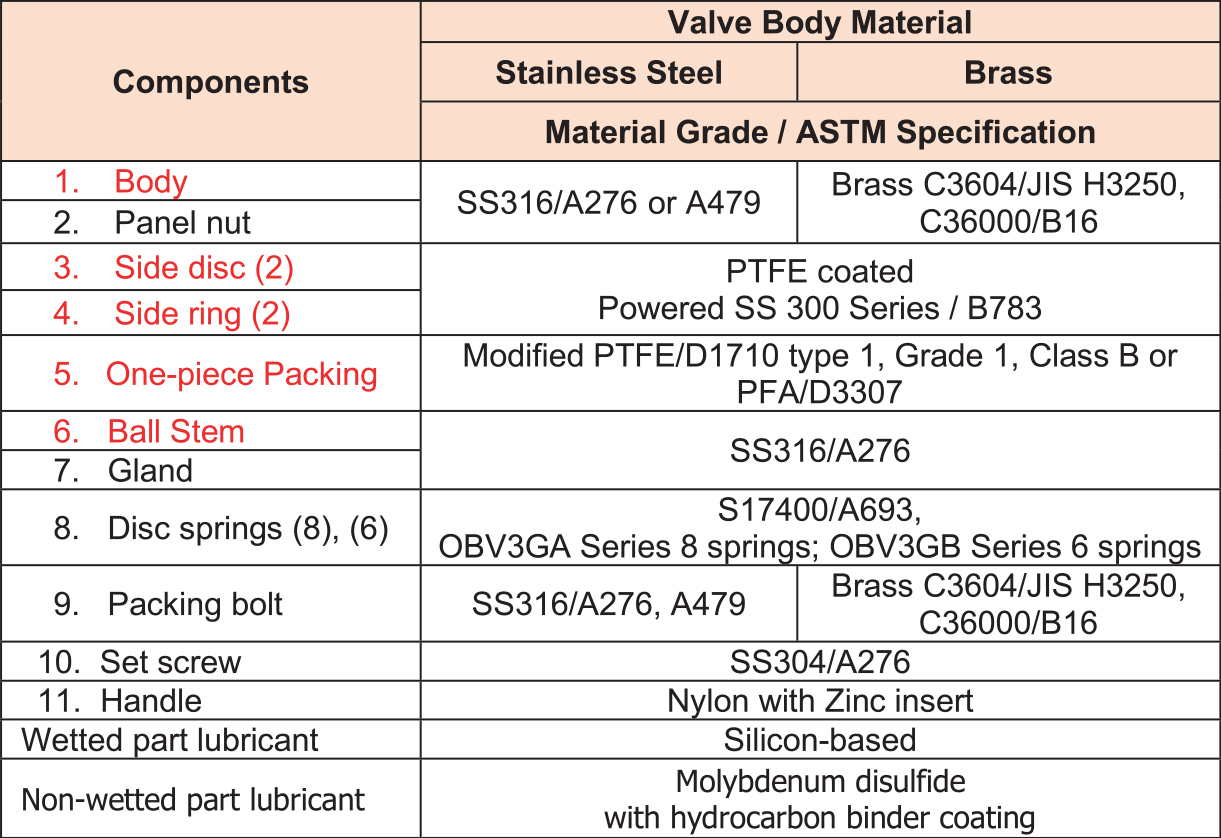

Valves are cleaned, packed, and labeled in accordance with the requirements of ASTM G93 Level C.

OTG Oxygen cleaning standard of OCS-005 is established to meet the requirements. The wetted parts of the valves are lubricated with non-hydrocarbon lubricant. To order, add SC to the valve ordering number.

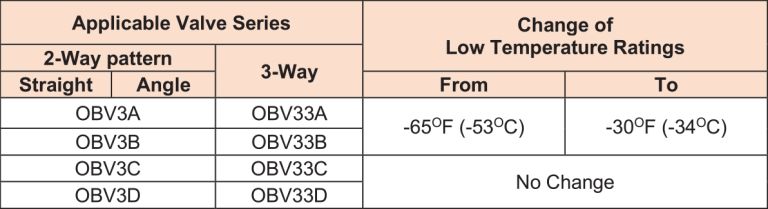

Specially cleaned 2-Way and 3-Way valves change the temperature rating.

Valve with no lubrication

Valves assembled with no lubrication are cleaned and packed in accordance with OTG Oxygen cleaning standard of OCS-05 in compliance with ASTM G93 Level C. To order, add NL to the valve ordering number.

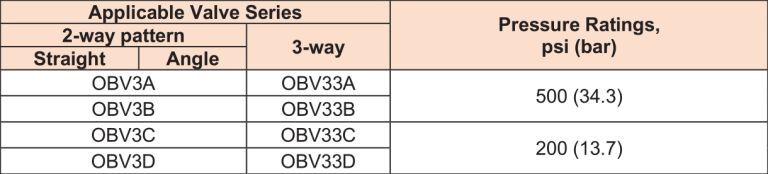

Valves assmbled with no lubrication changes the pressure rating

Note: Valves assembled with no lubrication have a significantly higher actuation torque than valves with lubricant.

Sour Gas Service

Stainless Steel OBV3 Series ball valves for service in sour gas application are available. Valve's wetted parts are selected to the requirements Of NACE MR0175/ISO 15156 for sulfide stress cracking resistant materials. To order, add SG to the valve ordering number.

Safe Valve Selection

The selection of a valve for any application or system must be considere to ensure safe performance. Valve rating, valve function, materal compatibility, proper installation, operation, and maintenance remain the sole responsibility of the system designer and the user. OTG Corporation accepts no liability for any improper selection, compatibility, installation, operation, or maintenance.