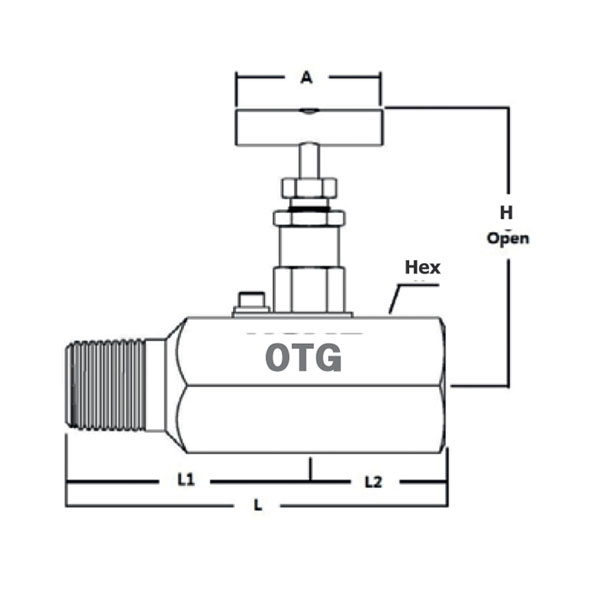

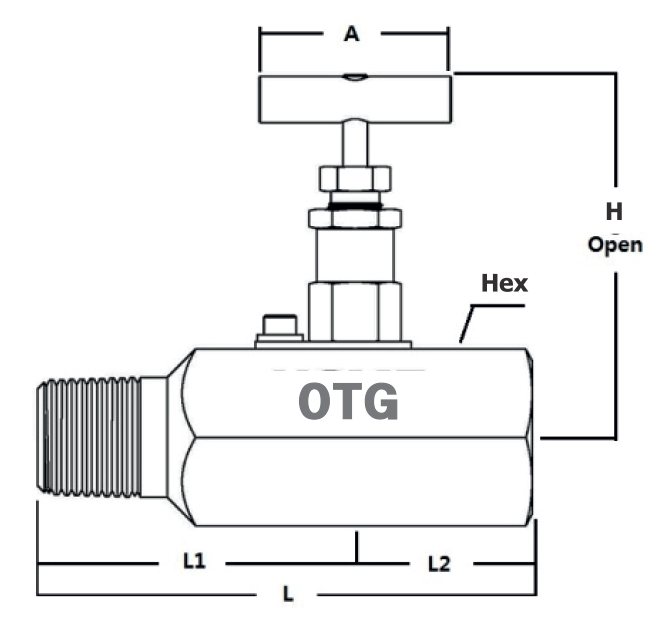

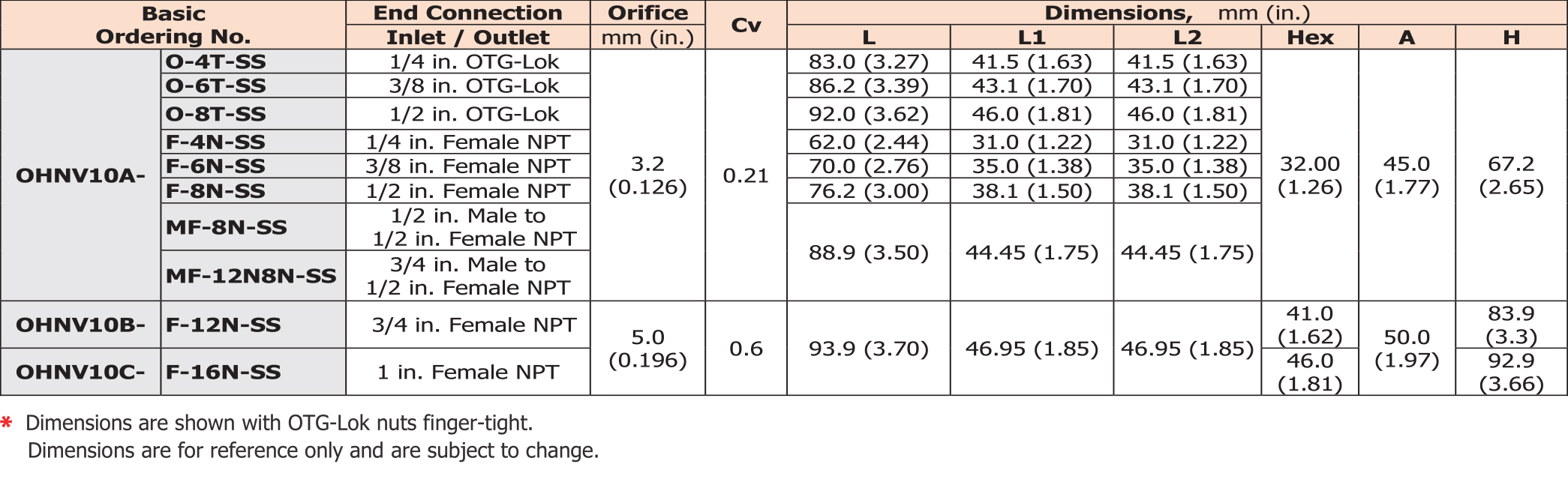

OHNV10 Series

High Pressure Needle Valves

Working Pressure: 10,000 psig (689bar)@100°F (37°C)

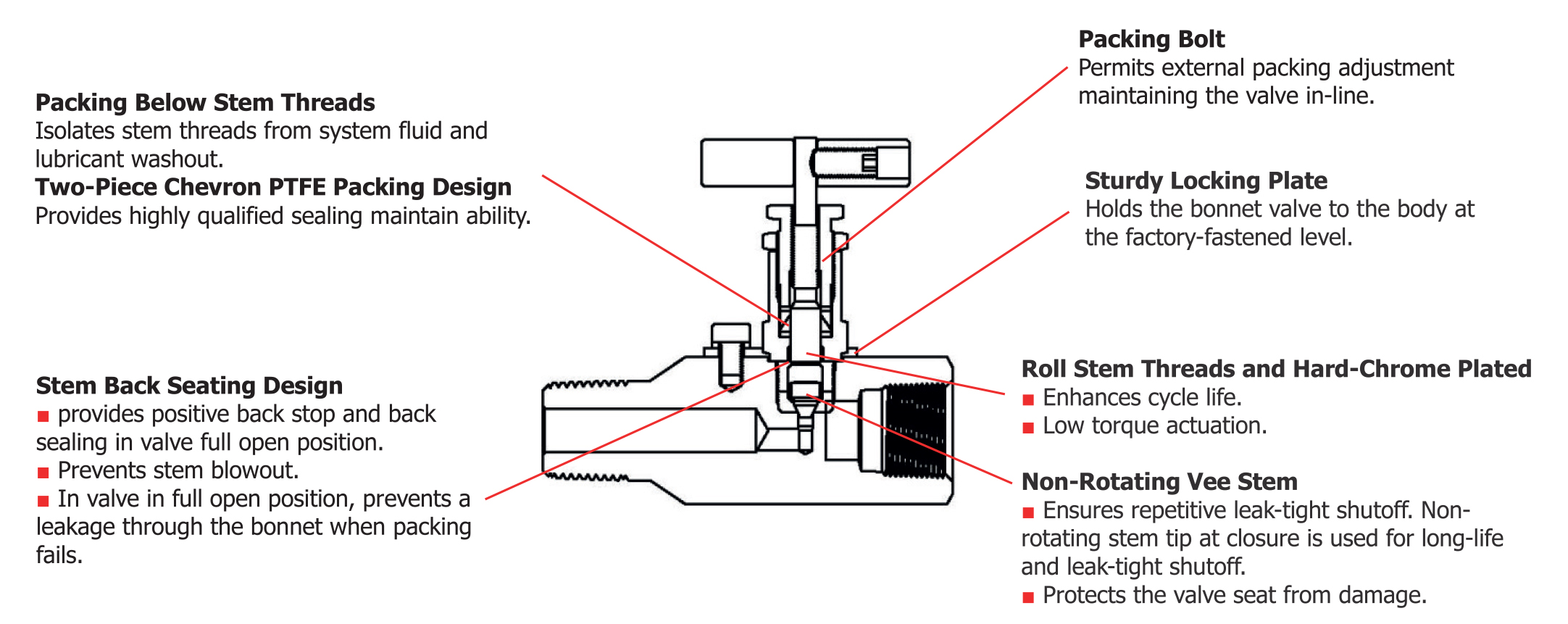

Features

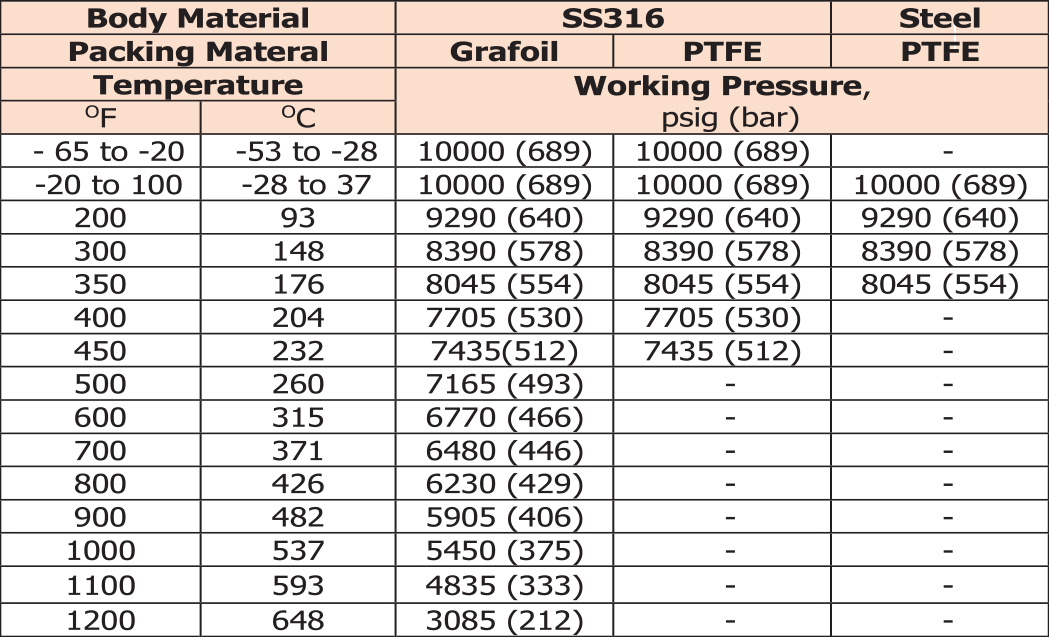

Temperature rating from -54"C (-65°F) to 232°C(450°F) with standard PTFE packing and up to 648°C(1200°F) with optional Graphite packing.

Body Construction

Construction out of robust cold-drawn Hex bar.

Bar handle

Allows low-torque valve actuation.

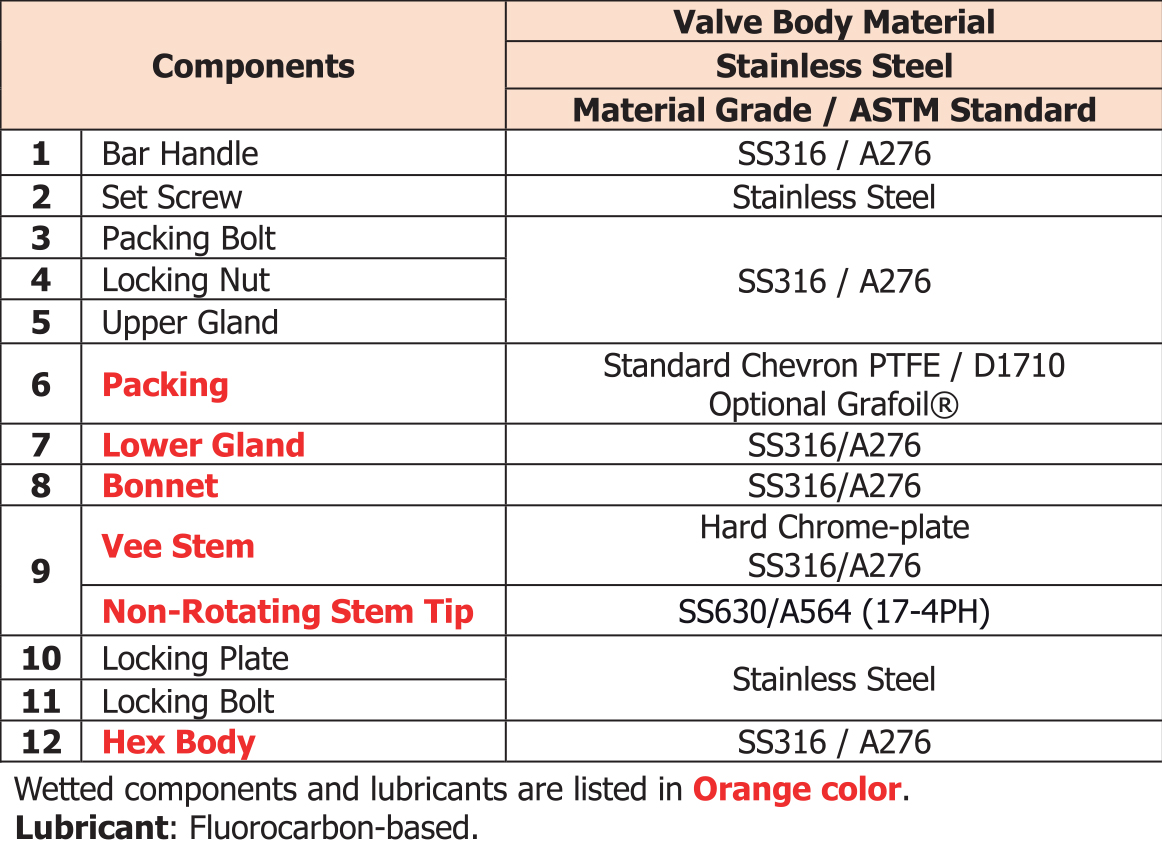

Grafoil Packing

Grafoil is high temperature packing material that requires a load to seal.

Grafoil is rated to the maximum of 973°F (523°C) for air service. In steam, it is rated to the maximum temperature of 1200°F (648°C).

Grafoil packing is not for use with pneumatic valves.

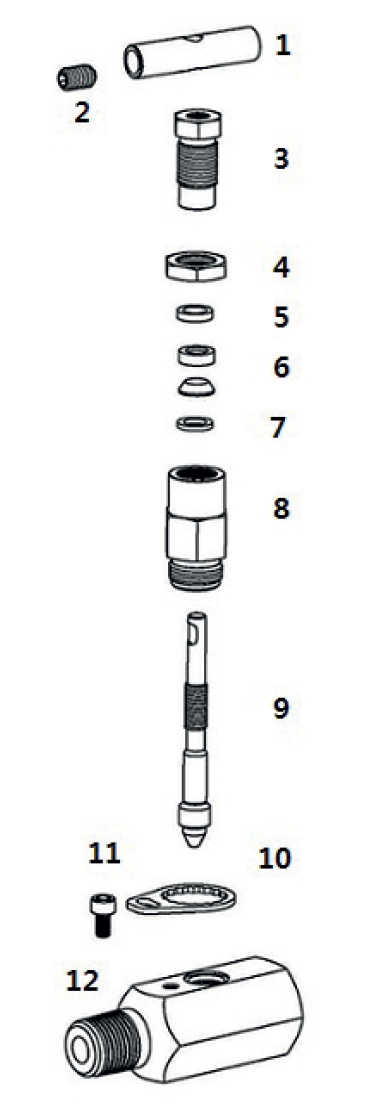

Materials of Construction

Pressure-Temperature Ratings

Factory Test and Cleaning

- Every valve is factory tested with nitrogen @1000 psig (69 bar) for leakage at the seat to a max. allowable leak rate of 0.1 std cm3/min.

- Packing seal is tested to no detectable leakage with a liquid leak detector.

- Every valve is cleaned and packaged in accordance with OTG's cleaning standard OCS-01.

Operation

- Valves that have not been cycled for a period of time may have a higher initial actuation torque.

- Packing adjustment may be required in service, especially for soft-seat stem to compensate its physical compression.

- Soft seat stem is recommended for gaseous and low density fluids, the shut-off torque should not exceed 7.9 Um. (70lb. in.).

Options

Sour Gas Service

The materials of wetted components are selected in accordance with NACE MR0175/ISO 15156-2/3 or NACE MR0103 depending on the application.

To order, add "SG" to the valve ordering number.

Grafoil Packing

Grafoil is high temperature packing material that requires a load to seal.

Grafoil is rated to the maximum of 973 °F (523 °C) for air service. In steam, it is rated to the maximum temperature of 1200 °F (648 °C).

Grafoil packing is not for use with pneumatic actuating valves.

Safe Valve Selection

The selection of a valve for any appliction or system must be considered to ensure safe performance. Valve rating, valve function, material compatibility, proper installation, operation and maintenance remain the sole responsibility of the system designer and the user. OTG Corporation accepts no liability for any improper selection, compatibility, installation, operation or maintenance.