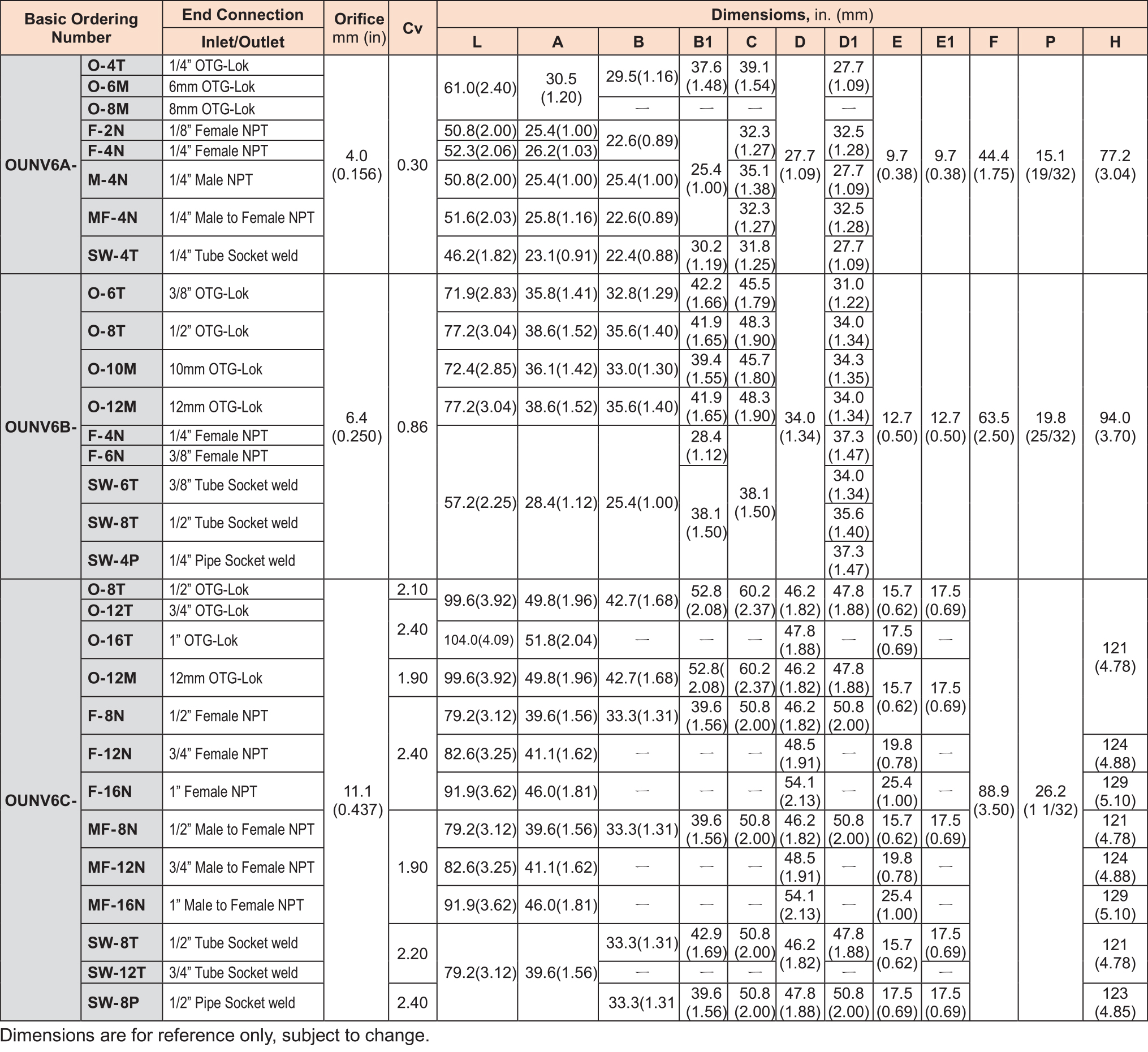

OUNV6 & OUNV1O Series

Severe-Service Union Bonnet Needle Valves

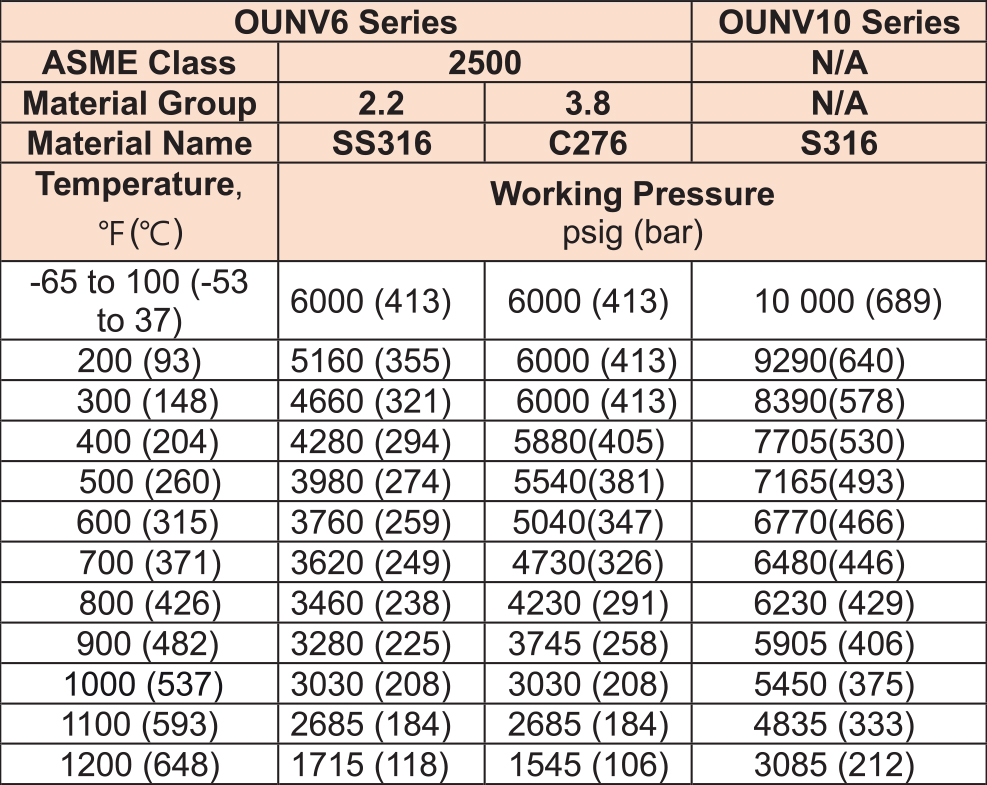

Working pressure up to 6000 psig (689 bar) @ 100°F (38 °C): OUNV6 Series

Working pressure up to 10,000 psig (689 bar) @ 100°F (38 °C): OUNV10 Series

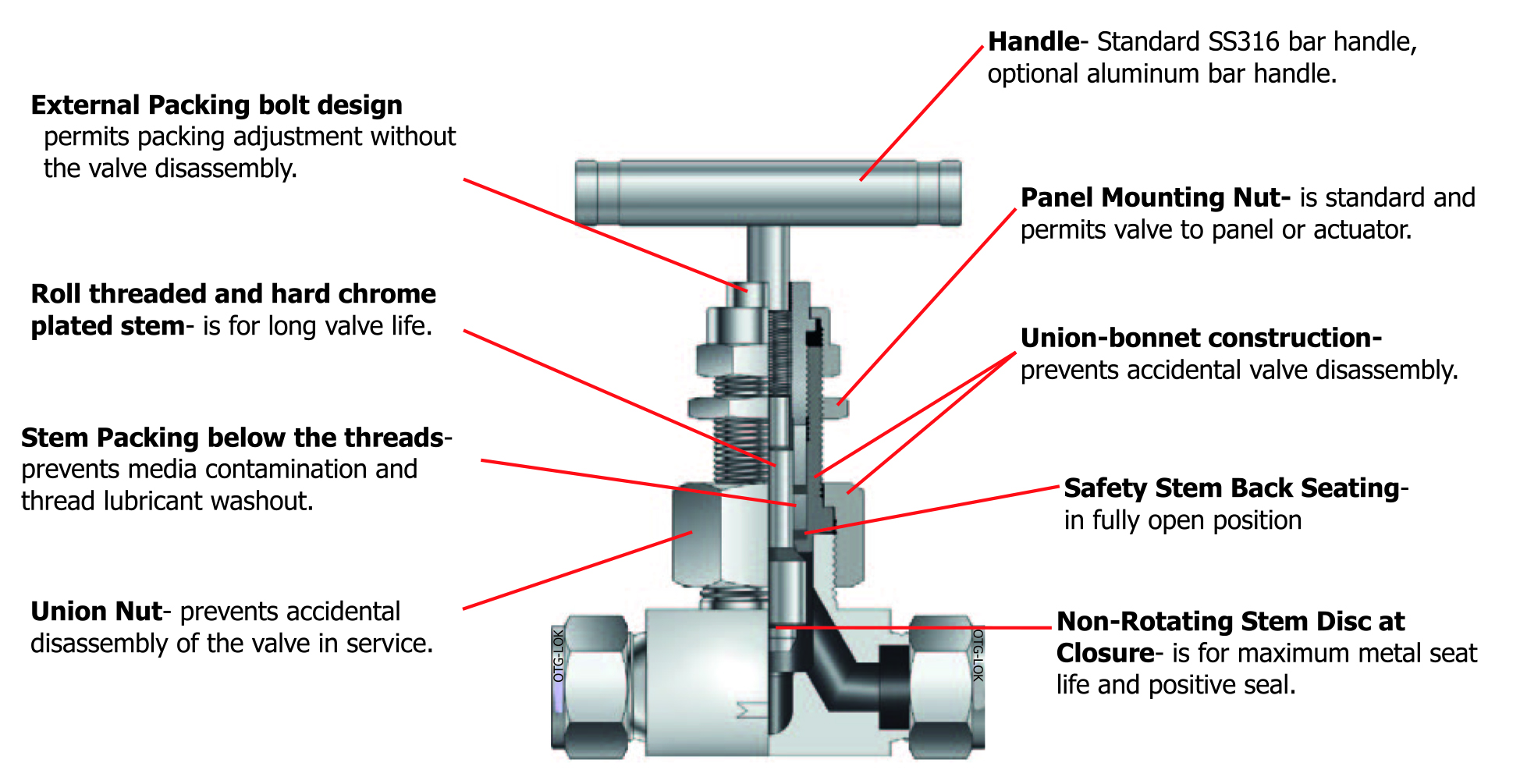

Features

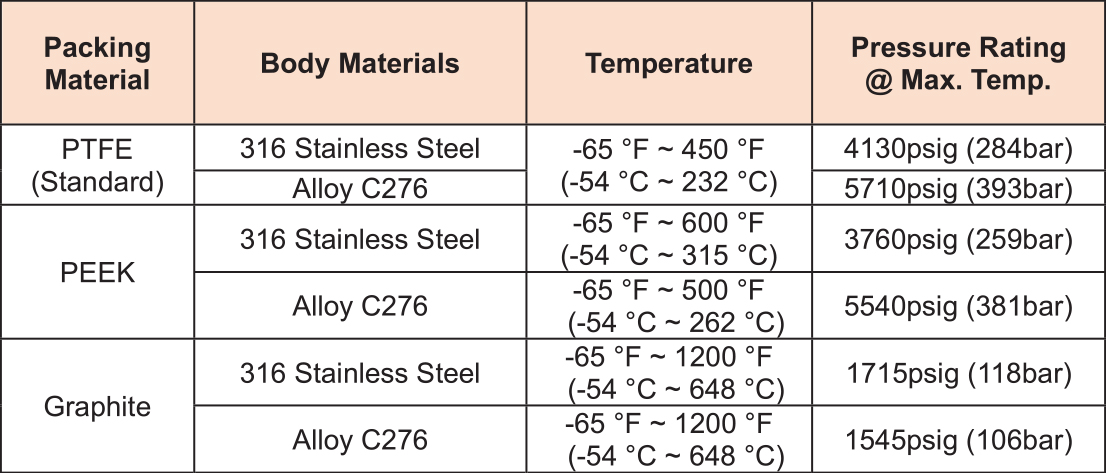

■ Temperatures from -65 to 450°F (-53 to 232°C) with PTFE packing; up to 1200°F (648°C) with optional Grafoil® packing

■ 316 stainless steel; Alloy C276 Materials.

■ 100% factory tested.

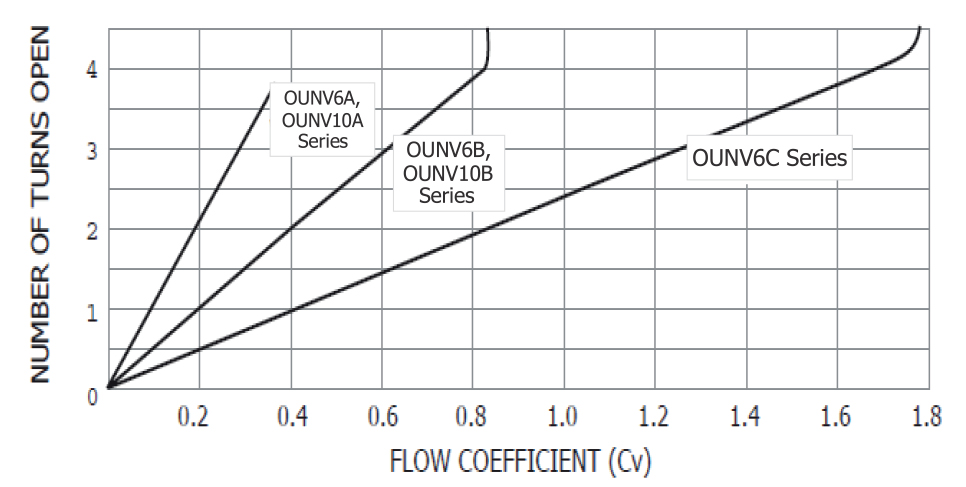

Number of Handle Turns-Cv

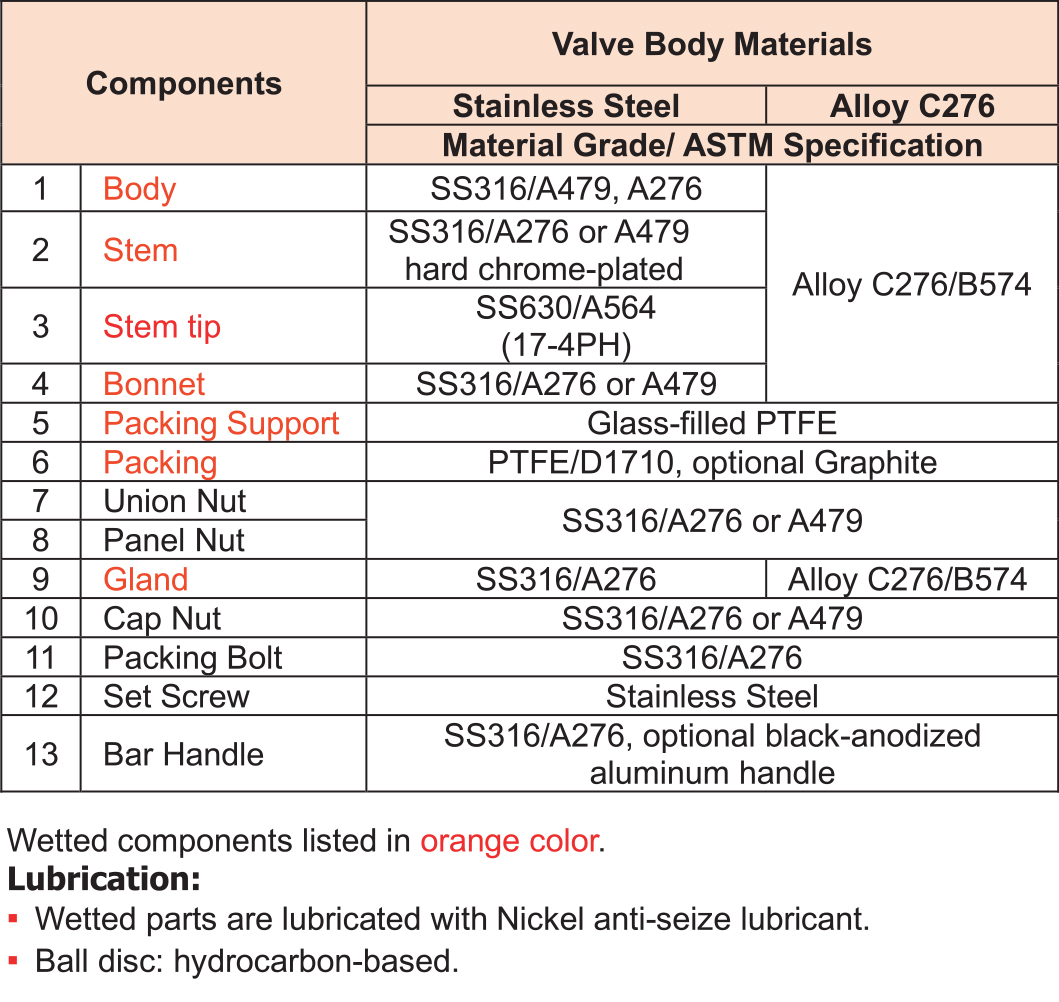

Clobe and Ball Disc

Valve with atandard globe and ball desc is designed for use in a fully open or fully closed position.

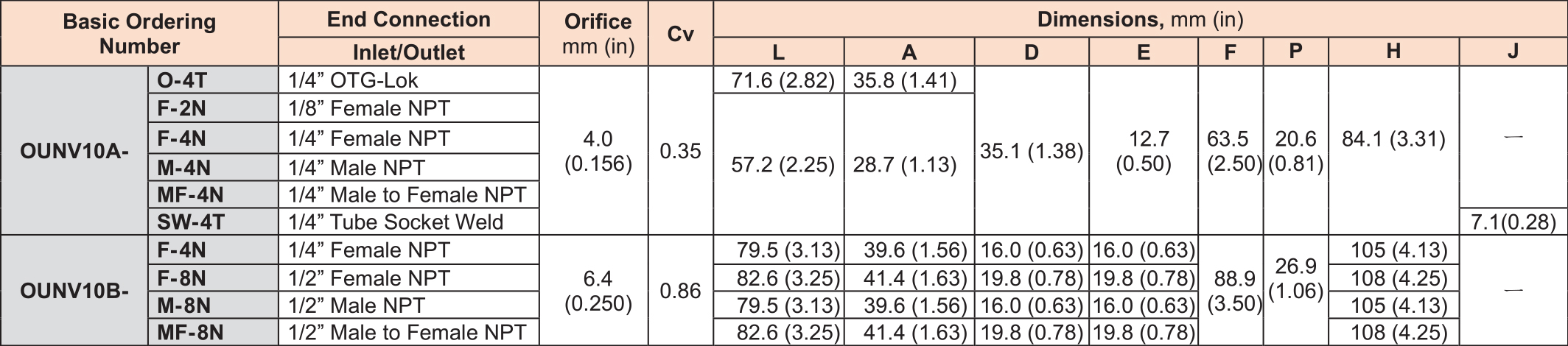

Refer to Cv in the ordering information and dimensions table on Page 3.

Cv reduction

Valve flow may be reduced by the restriction of pipe and tubing connected.

Sour Gas Valves

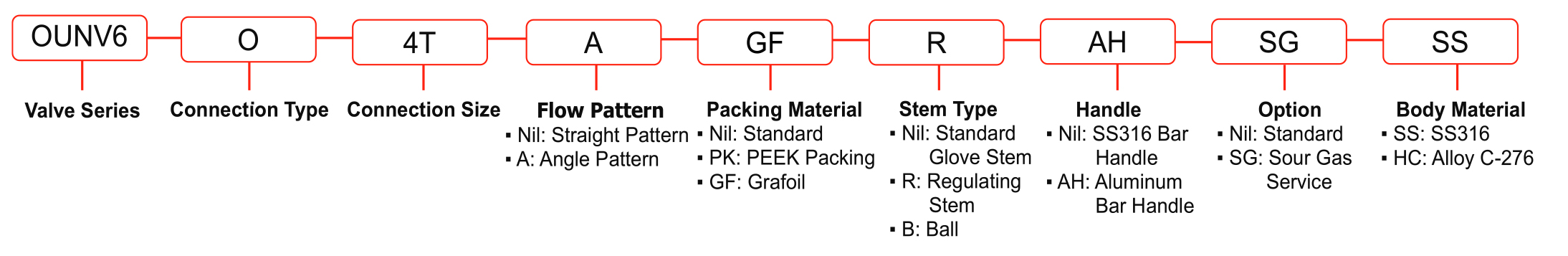

Valves for use in sour gas are available. Valve wetted components are selected to the requirements of VACE MR0175 for sulfide stress cracking resistant materials. To order, insert-SG in the basic ordering number.

Grafoil packing information

Grafoil is a high temperature packing material that requires a load on the material to generate a seal.

In air, Grafoil maximum temperature is 973°F (523°C), in steam, Grafoil goes up to the maximum temperature of 1200°F (648° C). Grafoil packing is not for use with pneumatic actuating valves.

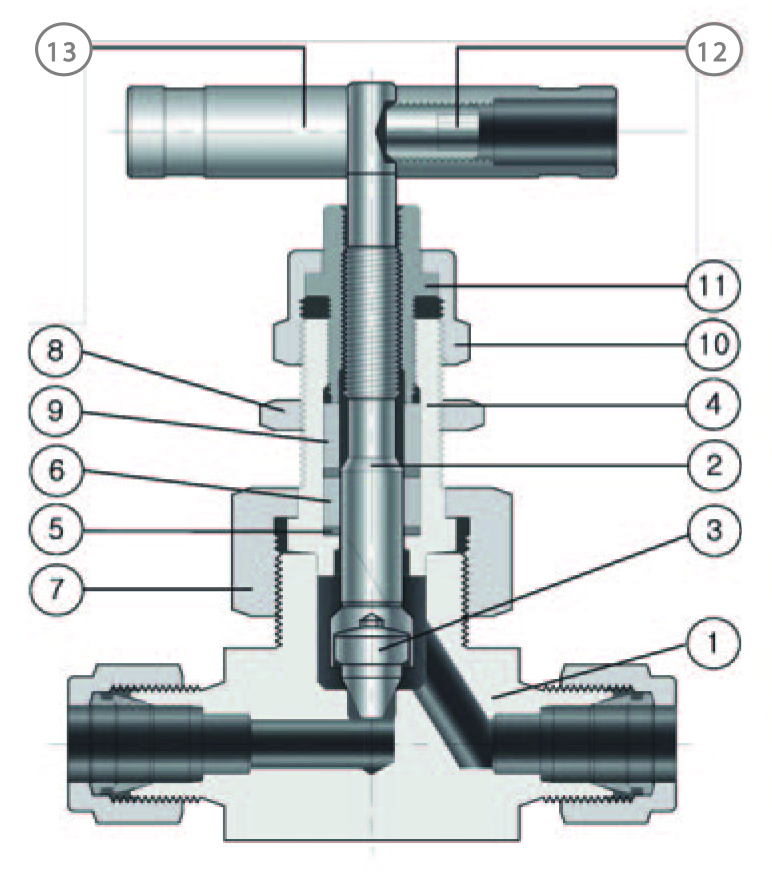

Materials of Construction

Testing

Every OUNV6 series and OHUNV10 series needle valve is factory tested with nitrogen at 1000 psig (69 bar). Seats have a maximum allowable leak rate of 0.1 std cm3/min. Shell testing is performed to a requirement of no detectable leakage with a liquid leak detector.

Cleaning

Every valve is cleaned and packaged in accordance with OTG cleaning standard OCS-01.

SAFETY in VALVE SELECTION

Proper installation, material compatibility, operation and maintenance of the valve is the responsibility of the user. The total system design must be taken into consideration to ensure optimal performance and safety.