OLCV6

Lift Check Valves

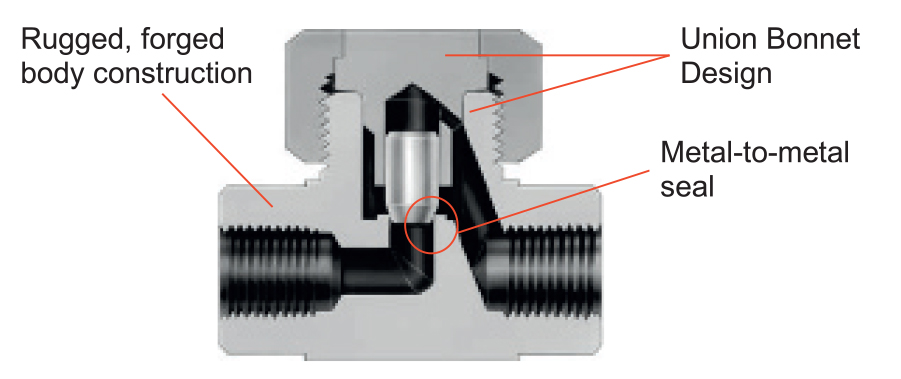

Features

■ OTG Lift Check Valve has been designed for a wide variety of temperature extremes found in power, chemical, petrochemical, oil & gas, and laboratory applocations.

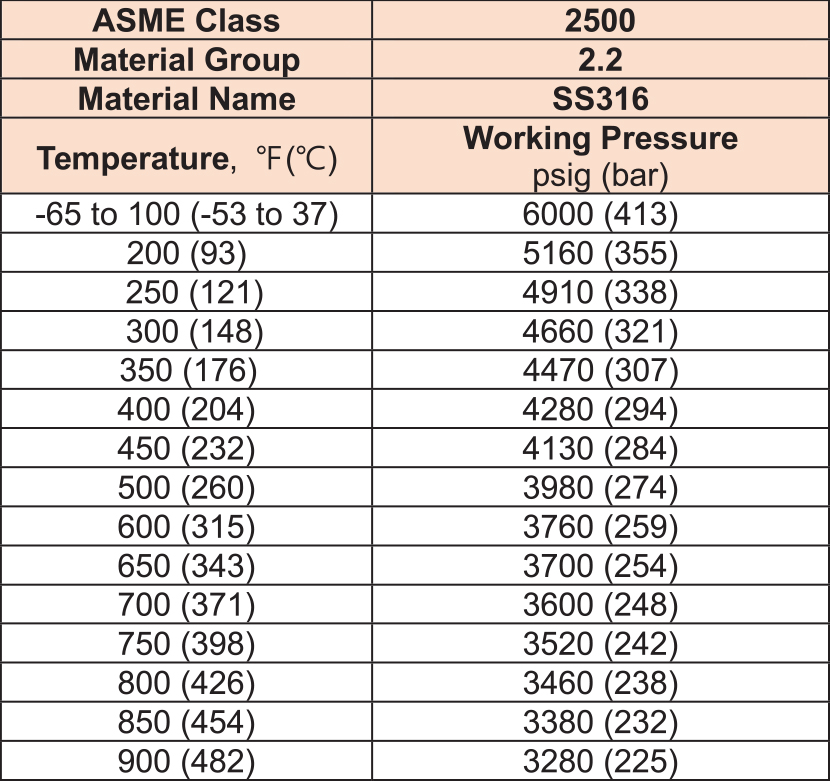

■ Pressure rating up to 6,000psi (413bar) @100°F(38°C)

■ Temperature up to 900°F(482°C)

■ SS316 stainless steel construction.

■ No spring or elastomers.

Operation

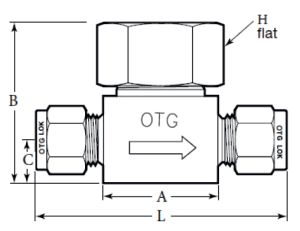

■ Forward flow lifts the poppet, opening the valve.

■ Reverse flow seats the poppet against the orifice, closeing the valve.

■ Reverse flow coefficient less than 0.1% of forward flow coefficient.

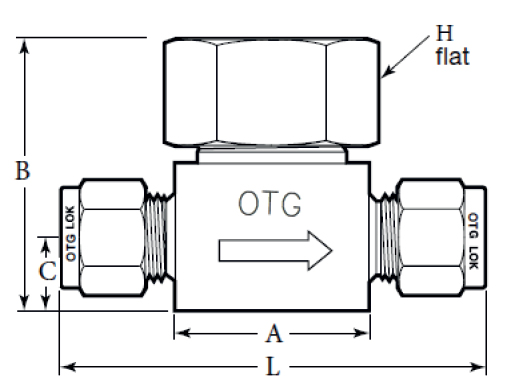

■ The lift check valve is gravity assisted poppet uses back pressure to achieve a seal and must be mounted horizontally, with bonnet nut on top.

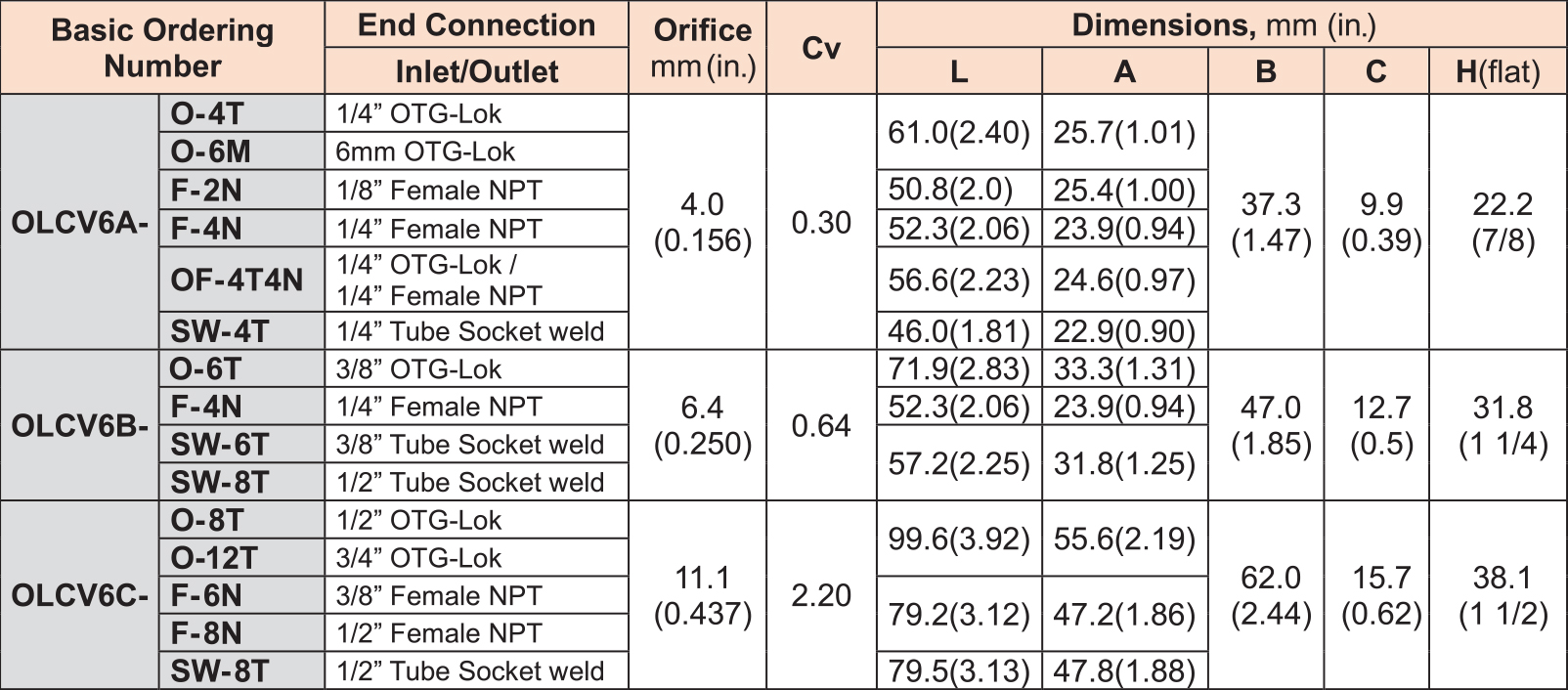

How to Order

To order, add the valve body material as s suffix to the basic ordering number.

EX) Stainless: -SS

Option

Cryogenic Service

The OTG Lift Check valve with PCTFE seat provides leak tight shutoff for Cryogenic service.

Temperature Rating: -238°F(-150°C) ~ 356°F(180°C)

Cracking Pressure: 10psig (0.69bar)

To order a Lift Ckeck valve for Cryogenic Service. add CS to the basic ordering number. Example: OLCV3-O-8T-CS-SS

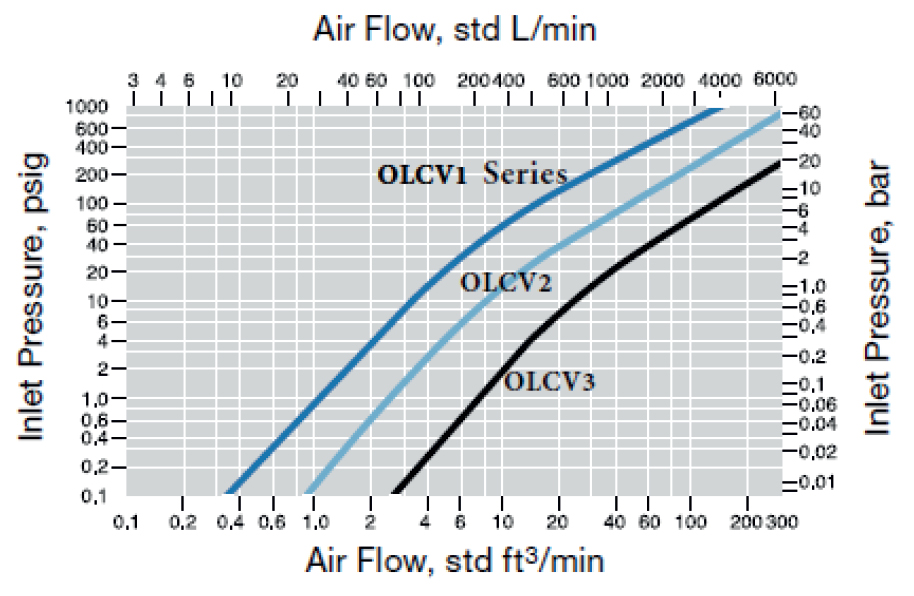

Flow Data

Every valve is tested for open and reseal performance using hydraulic fluid.

Causion

SAFETY in VALVE SELECTION

Proper installation. material compatibility, operation and maintenance of the valve is the responsibility of the user. The total system design must be taken ivto consideration to ensure optimal performance and safely.