OPGV

Purge Valves

Features

■ Working Pressure up to 4,000psi (275 bar)

■ Temperature up to 600°F(315°C)

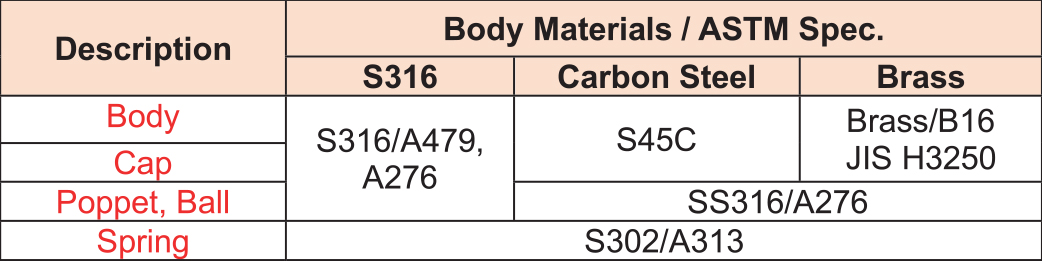

■ 316 stainless steel, brass, or carbon steel materials.

■ Compact for convenient installation

■ Size range from 1/8" to 1/2" Tubing and piping system.

■ Variety of End connections include OTG-Lok, NPT & ISO threads Male / Female

Operation

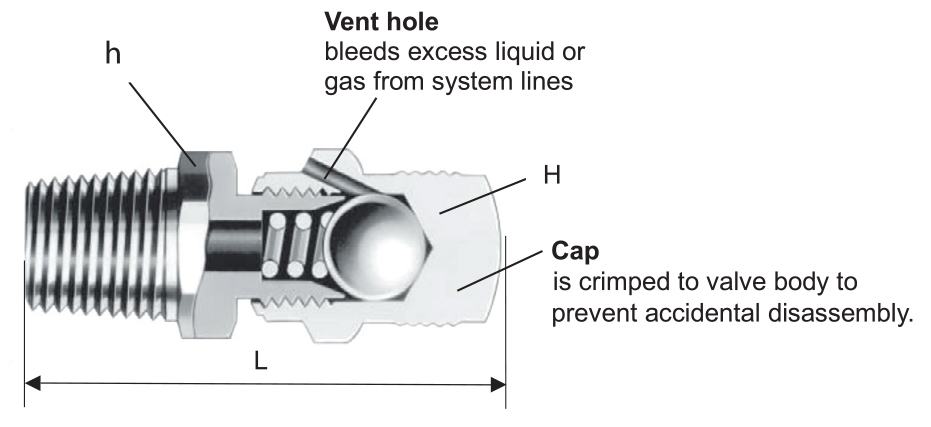

■ OTG purge valves are manual bleed, vent, or drain valves. The knurled cap is permanently assembled to the valve body for safety.

■ One-quarter turn with a wrench from finger-tight obtains Leak tight closure on first makeup. Snugging with a wrench ensures closure to the rated pressure with subsequent makeups.

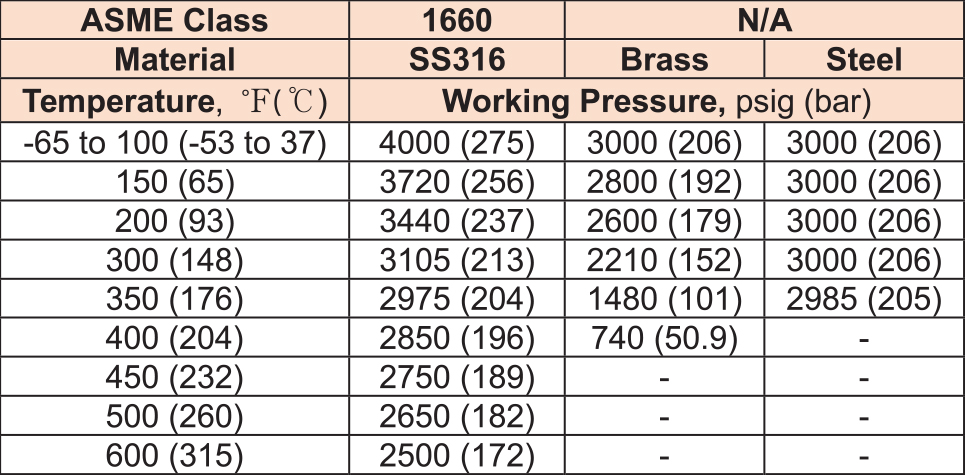

Pressure-Temperature Ratings

Rating limited to:

■ -20°F(-28°C) min steel

■ 450°F(232°C) max with SAE end connections using fluorocarbon FKM O-ring.

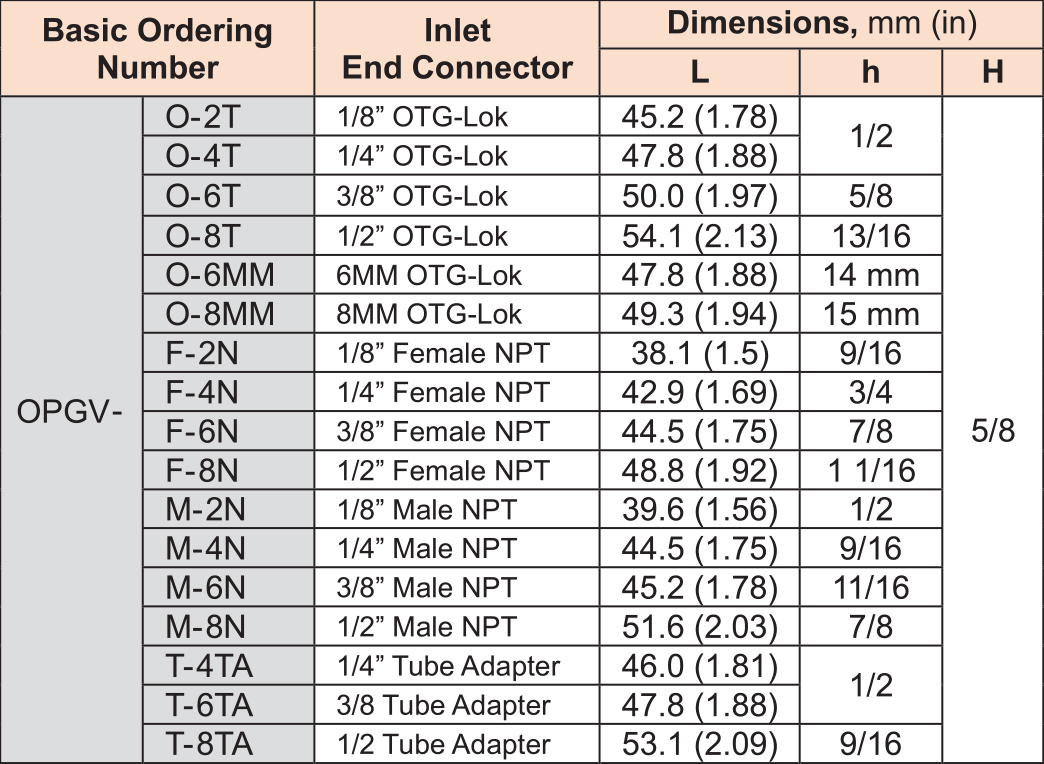

How to Order

To order, add the valve body material as a suffix to the basic ordering number.

Stainless: SS, Carbon Steel: CS, Brass: BS

Option

The OTG purge valve with PTFE ball provides leak tight shutoff with finger pressure and features a removable cap for easy ball replacement.

Pressure Rating: 200 psig at 100°F (13.7 BAR AT 37°C)

Temperature Rating: 350°F (176°C).

To order a OTG purge valve with PTFE ball, add-TE to the ordering number. Example: OPGV-M-8V-TE-SS

Factory Test

Every valve is tested with nitrogen at 1000psi(69bar) to maximum leak rate of 0.1 std cm3/min. The valve with PTFE ball is tested at 0.69bar (10psi) for leakage at the seat to maximum leak rate 0.1 std cm3/min.

Caution

When installing a OTG purge valve, posttion the vent hole to direct system fluid away from operating personnel. The vent hole rotates with the cap, changing the direction of discharge as the cap is turned.

Always open purge valves slowly. These valves contain no packing, so some fluid weepage will occur when the valves are opened.

Operating personnel must protect themselves from exposure to system fluids.