OBV6 Series

General Service Ball Valves

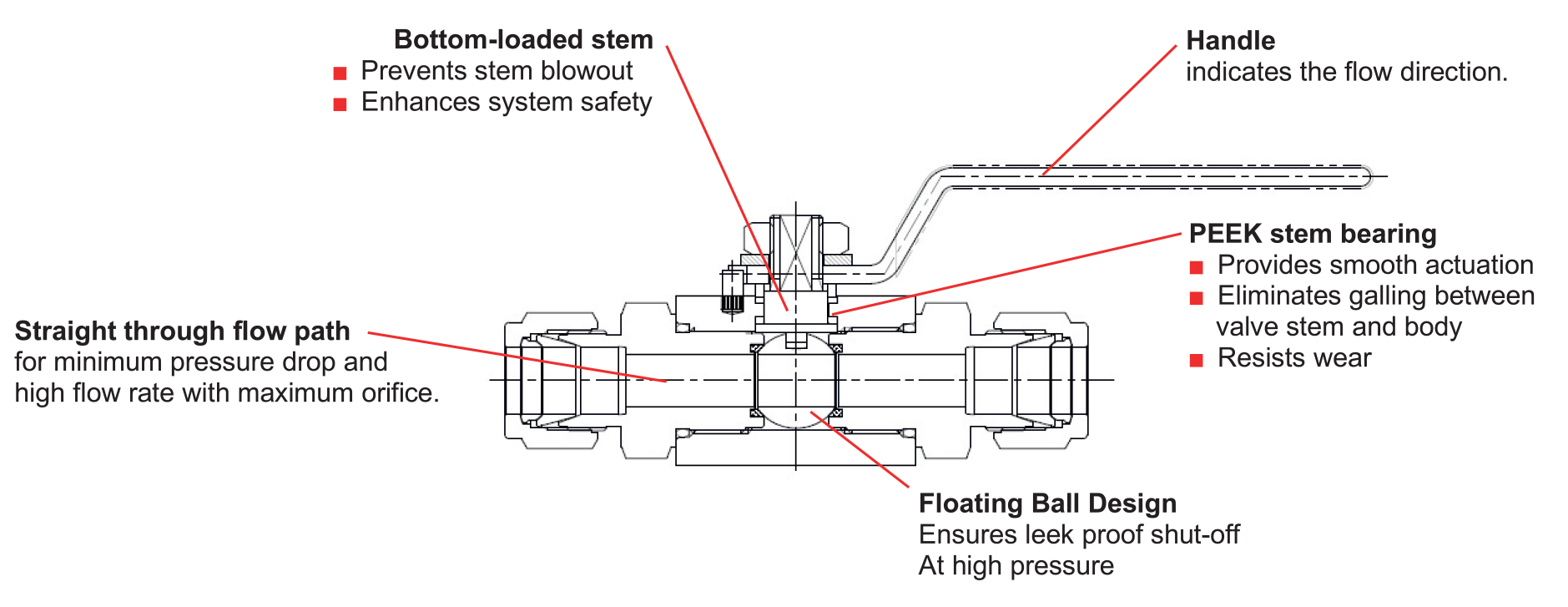

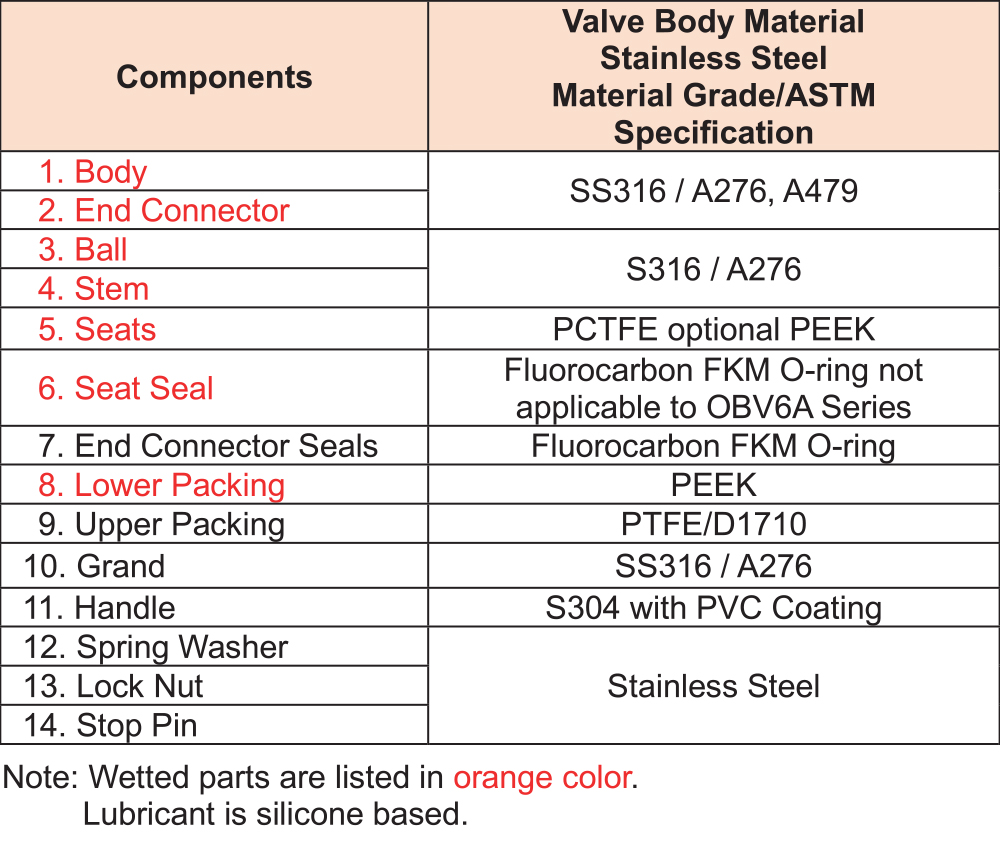

Features

■ Pressure rating up to 10,000psig (690var)@70°F(21°C).

■ Temperature rating from -22°F(-30°C) to 265°F(130°C) with PVDF seat

from -65°F(-54°C) to 500°F(260°C) with PEEK seat

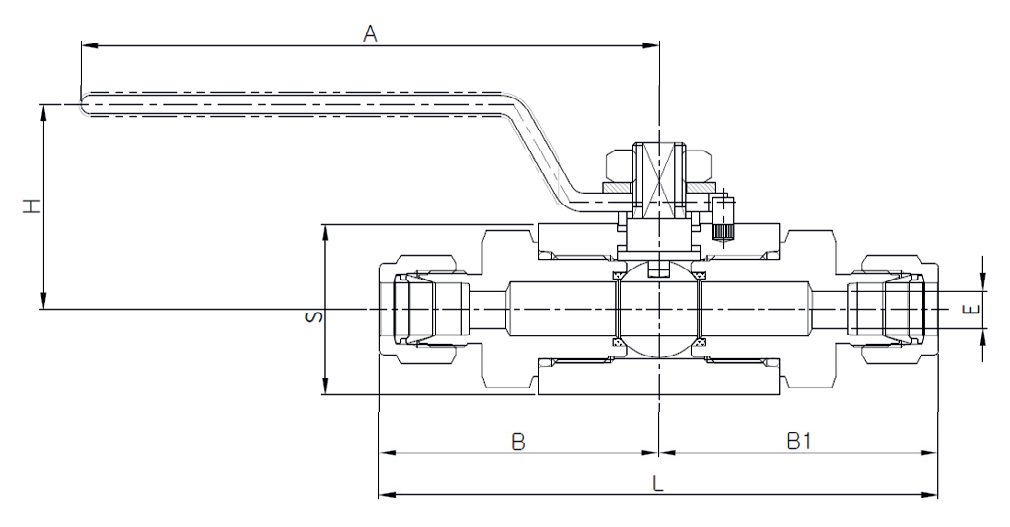

■ OTG-Lok tube fitting end connections in fractional (1/4 in. to. 1 in.) and metric (6 mm to 25 mm), female pipe end connections in fractional (1/4 in. to 1 in.)

■ Cold drawn bar construction.

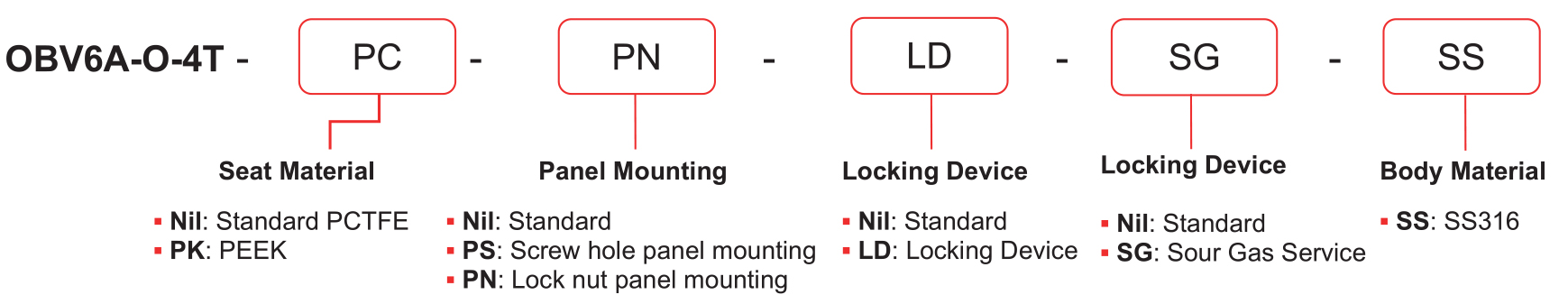

■ Panel mounting and locking devices are available as options.

■ Optional NACE MR0175-2001 for Sour Gas.

■ Outstanding sealing performance across the pressure range.

Application

■ Provide quick turn on-off control of fluids in process, power and instrumentation applications.

■ All ports are suitable as inlets in full operation pressure of the valve.

■ A broad selection of valve body, seat, and seal materials provide a wide range of pressure and temperatures at which the valve may be used.

■ Designed for gas, liquid, and vacuum service provides a reliable sealing performance in wide range high duty applications.

Operation

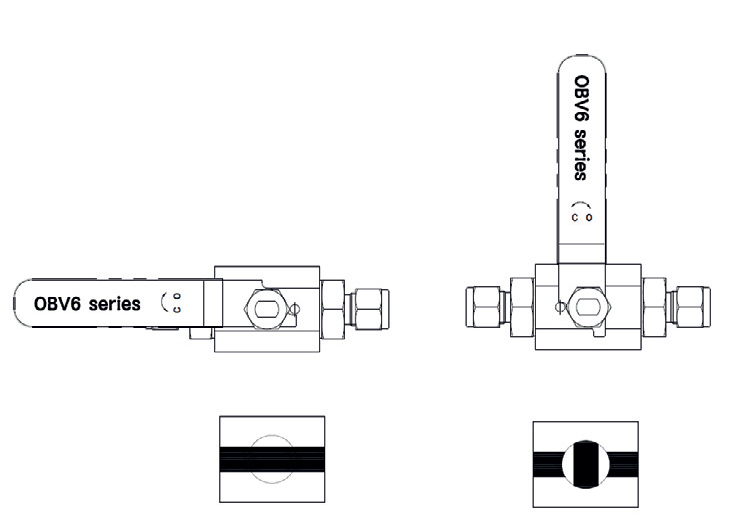

■ 2-way valves are designed to control fluid bi-directionally in full open and full close position.

■ Valves that have not been actuated for a period of time may have a higher actuation torque

2-Way

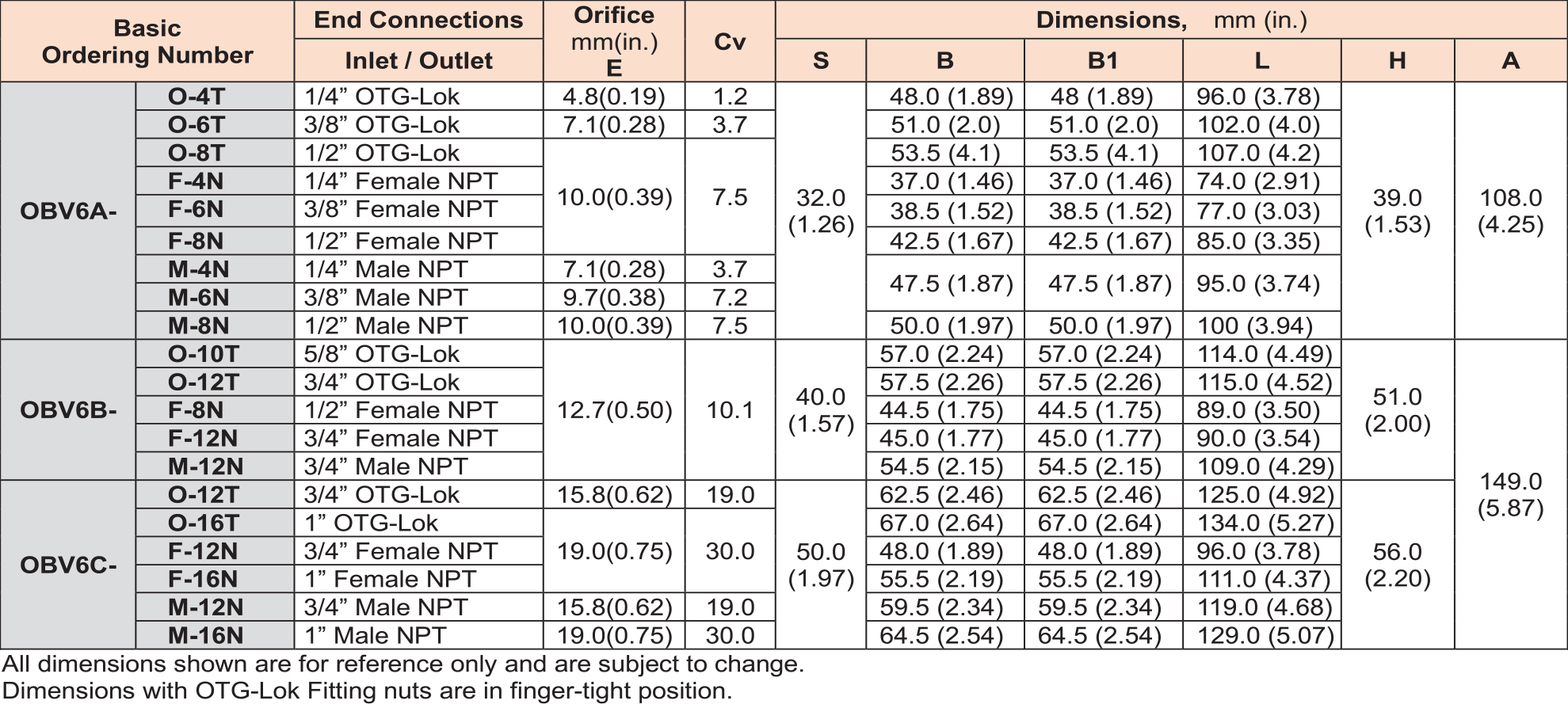

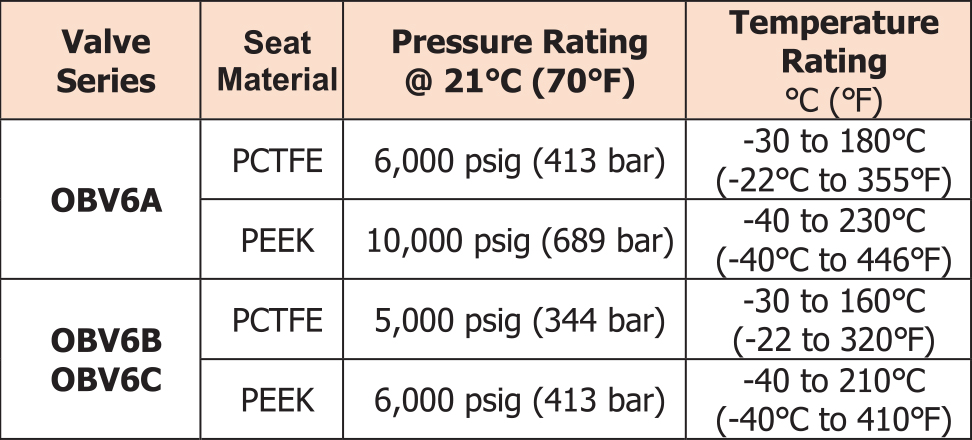

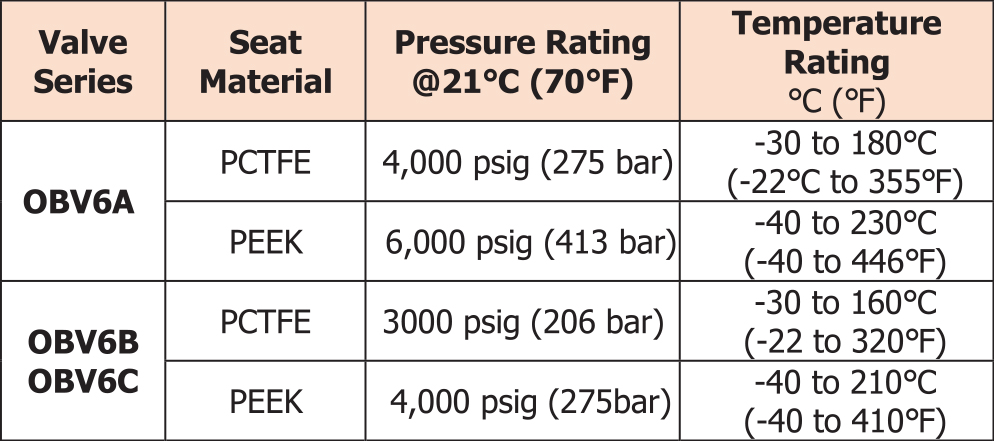

Pressure and Temperature Rating

Note:

■ The rated pressure shown above is the maximum allowable pressure to the seat. If the system requires higher pressure to test, the valve must be in open position before and during test so as not to damage the seat.

■ Pressure ratings of valves are sometimes limited to the maximum working pressure of pipe ends and tubing connected. The working pressure of tubing must be considered in the calculation of total system working perssure.

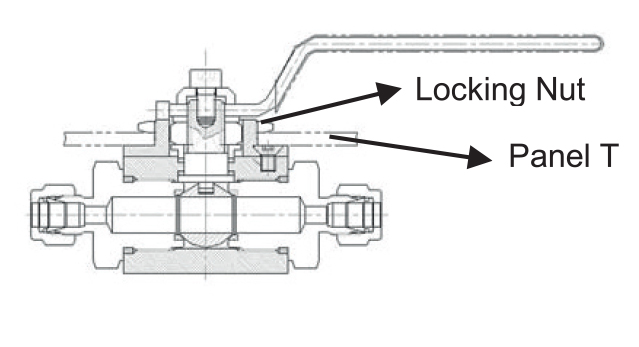

Locking device option

Ordering designator: LD

Locking device option is applicable to 2-way and 3-way valve.

The valve with locking device is manually locked out in the valve open or close position. For additional security, apply padlock.

The Padlock applicable hole is 7.2 mm(0.28 in.) and is constructed above the upper lock detent.

Note:LD option applicable to 2-way valves.

Sour Gas Service

■ Is provided to meet NACE Standard MR0175/ISO 15156-3. To order valve for sour gas application, insert "SG" to the valve basic ordering number. Example: OVC6A-O-4T-SG-SS

Testing and Cleaning

■ Every valve is factory tested with nitrogen @ 1000 psig (69 bar)) for leakage at the seat to a maximum allowable leak rate of 0.1 SCCM.

■ The packing is tested with nitrogen for no detectable leakage.

■ Every valve is cleaned and packaged in accordance with OTG cleaning standard.

Safety in Valve Selection

The selection of a valve for any application or system must be considered to ensure safe performance. Valve rating, valve function, material compatibility, proper installation, operation and maintenance remain the sole responsibility of the system designer and the user.

OTG Corporation accepts no liability for any improper selection, compatibility, installation, operation, or maintenance.